|

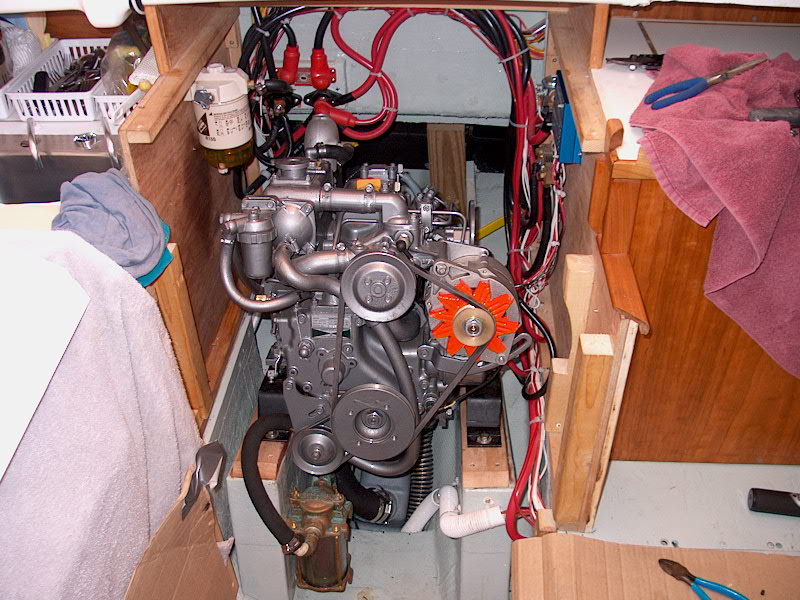

Yanmar 2GM20F:

Installation, Alignment, and Hookups

This page was last updated on 8

August 2001.

TUESDAY 7/31/01

After

spending the morning preparing the engine

beds and using my template to properly set the mounts for the engine

alignment, I drove home to pick up the new Yanmar. Back at the yard, I

reversed the process used to get the old SB12 out of the boat, and swung the

boom out over the side so I could hoist the engine out of my truck and into the

cockpit. This went smoothly, even though I was

"performing" in front of the lunch crowd at the nearby

restaurant. As before, I set the engine in the cockpit well, then moved

the hoist forward and raised the engine up to the bridgedeck. Here I

paused, and installed the four flexible engine mounts in their proper

positions. I had marked them before when I was using the template to get

the rough alignment right. After

spending the morning preparing the engine

beds and using my template to properly set the mounts for the engine

alignment, I drove home to pick up the new Yanmar. Back at the yard, I

reversed the process used to get the old SB12 out of the boat, and swung the

boom out over the side so I could hoist the engine out of my truck and into the

cockpit. This went smoothly, even though I was

"performing" in front of the lunch crowd at the nearby

restaurant. As before, I set the engine in the cockpit well, then moved

the hoist forward and raised the engine up to the bridgedeck. Here I

paused, and installed the four flexible engine mounts in their proper

positions. I had marked them before when I was using the template to get

the rough alignment right.

|

|

Setting up the hoist one final time, I swung

the engine through the companionway, and lowered it down towards the engine

room. It was easy to move it as required, and soon I had it nearly sitting

on the beds. As I lowered, the forward mounts came into contact with the

beds first, to help me keep things in position I partially installed the two

forwardmost lag screws on the forward

mounts. Then, I continued lowering the engine until the after mounts were

resting on the engine foundation. Note that I had removed the alternator

for two reasons: to make it a little easier to get the engine in place

(without the alternator projecting from the side) and I am replacing the stock

alternator with the high capacity large-frame alternator I used on my other

engine, and around which my electrical and charging systems are

constructed. The 55-amp alternator that came with the engine would be

fine, but it is internally regulated and therefore incompatible with my external

smart regulator. Setting up the hoist one final time, I swung

the engine through the companionway, and lowered it down towards the engine

room. It was easy to move it as required, and soon I had it nearly sitting

on the beds. As I lowered, the forward mounts came into contact with the

beds first, to help me keep things in position I partially installed the two

forwardmost lag screws on the forward

mounts. Then, I continued lowering the engine until the after mounts were

resting on the engine foundation. Note that I had removed the alternator

for two reasons: to make it a little easier to get the engine in place

(without the alternator projecting from the side) and I am replacing the stock

alternator with the high capacity large-frame alternator I used on my other

engine, and around which my electrical and charging systems are

constructed. The 55-amp alternator that came with the engine would be

fine, but it is internally regulated and therefore incompatible with my external

smart regulator.

With the engine sitting squarely on all four

mounts, I installed the lags and partially threaded them in. I removed the

hoist and cleared things out a bit to give me room to work. I made sure

that the engine was in the proper place, and that the mounts were all lined up

with the engine--it's easy for them to get cockeyed a bit. I needed a

little crowbar persuasion to get the aft port mount properly aligned so I could

install the after lag screw. Then, I tightened down all the lags, leaving

them only slightly loose so I could move the engine if necessary to affect the

alignment.

|

|

Moving

into the cockpit, I reached through the access hatch there and pulled the shaft

forward to check the rough alignment. The couplings thunked together

nicely, indicating that the alignment was very close. The side-to-side and

up-and-down alignment seemed spot on, so all I had to worry about was the fine

face alignment of the couplings. Using a feeler gauge, I checked the coupling

alignment all the way around, and made some small adjustments to the

engine. It didn't take much--the alignment template is worth its weight in

platinum, and is certainly worth the effort required to build it. Then, I

cranked down all the lags, and tightened the adjusting nuts on the mounts.

I'll check alignment again once the boat is in the water. Cranking down

the lags required several transmogrifications of my 1/2" ratchet, including

long and short extensions, and no extensions at all, because of the tight access

in some locations. My arms were certainly tired afterwards. Moving

into the cockpit, I reached through the access hatch there and pulled the shaft

forward to check the rough alignment. The couplings thunked together

nicely, indicating that the alignment was very close. The side-to-side and

up-and-down alignment seemed spot on, so all I had to worry about was the fine

face alignment of the couplings. Using a feeler gauge, I checked the coupling

alignment all the way around, and made some small adjustments to the

engine. It didn't take much--the alignment template is worth its weight in

platinum, and is certainly worth the effort required to build it. Then, I

cranked down all the lags, and tightened the adjusting nuts on the mounts.

I'll check alignment again once the boat is in the water. Cranking down

the lags required several transmogrifications of my 1/2" ratchet, including

long and short extensions, and no extensions at all, because of the tight access

in some locations. My arms were certainly tired afterwards.

|

|

With

the mounts secured, I moved on to install the new Yanmar flexible coupling (Part

# 104214-05450) and

attach the shaft to the engine. I used the new flexible coupling in place

of the Drivesaver I had previously on the recommendation of my engine

supplier--the new one is two slabs of steel surrounding a heavy-duty rubber

core. This absorbs the movement of the engine (the result of the flexible

engine mounts) and will also serve as a sort of "circuit breaker"

should the propeller come into contact with an immobile object--breaking the

coupling instead of the transmission. The flexible coupling features studs

on each side, and I secured it first to the transmission coupling, then secured

the shaft coupling and shaft to the other side, using nylock nuts. Working

upside down through my (thankfully) large cockpit hatch, securing the eight nuts

took over a half hour, leaving me feeling woozy. With

the mounts secured, I moved on to install the new Yanmar flexible coupling (Part

# 104214-05450) and

attach the shaft to the engine. I used the new flexible coupling in place

of the Drivesaver I had previously on the recommendation of my engine

supplier--the new one is two slabs of steel surrounding a heavy-duty rubber

core. This absorbs the movement of the engine (the result of the flexible

engine mounts) and will also serve as a sort of "circuit breaker"

should the propeller come into contact with an immobile object--breaking the

coupling instead of the transmission. The flexible coupling features studs

on each side, and I secured it first to the transmission coupling, then secured

the shaft coupling and shaft to the other side, using nylock nuts. Working

upside down through my (thankfully) large cockpit hatch, securing the eight nuts

took over a half hour, leaving me feeling woozy.

Note that the photos shows my

half coupling and flexible coupling after I repainted them; the red color is not

standard.

|

|

As

I still had some time left in the day, I spent some of it reattaching the

exhaust hose to the engine. Using the same length of hose from the old

engine, I determined a new route for it from the riser, down to starboard of the

transmission, and then forward to the Vetus Waterlock in the bilge beneath the

engine. This is a more direct--and more convenient--route than the hose

had to take with the old engine, and I was able to cut about 12" off the

hose. I secured it to the riser and Waterlock with double clamps. I

also reinstalled my raw water strainer, and attached the short length of hose

needed to run from the strainer to the inconveniently-located raw water pump on

the engine. (It's located on the back side of that pulley above the

strainer--meaning that changing the impeller should take about 9 times as long

as it should. This seems like poor design--I wonder why they did it this

way?) As

I still had some time left in the day, I spent some of it reattaching the

exhaust hose to the engine. Using the same length of hose from the old

engine, I determined a new route for it from the riser, down to starboard of the

transmission, and then forward to the Vetus Waterlock in the bilge beneath the

engine. This is a more direct--and more convenient--route than the hose

had to take with the old engine, and I was able to cut about 12" off the

hose. I secured it to the riser and Waterlock with double clamps. I

also reinstalled my raw water strainer, and attached the short length of hose

needed to run from the strainer to the inconveniently-located raw water pump on

the engine. (It's located on the back side of that pulley above the

strainer--meaning that changing the impeller should take about 9 times as long

as it should. This seems like poor design--I wonder why they did it this

way?)

|

This done, I called it quits for the day,

knowing that I was ahead of my initial aggressive schedule. Things were

going very well.

|

|

|

| Please click here

to continue the project--final hookups of the fuel and electrical systems, and

the cooling system.

|

|