|

Yanmar 2GM20F:

Templating and Foundation Modifications

This page was last updated on 2

August 2001.

TUESDAY 7/31/01

Bright

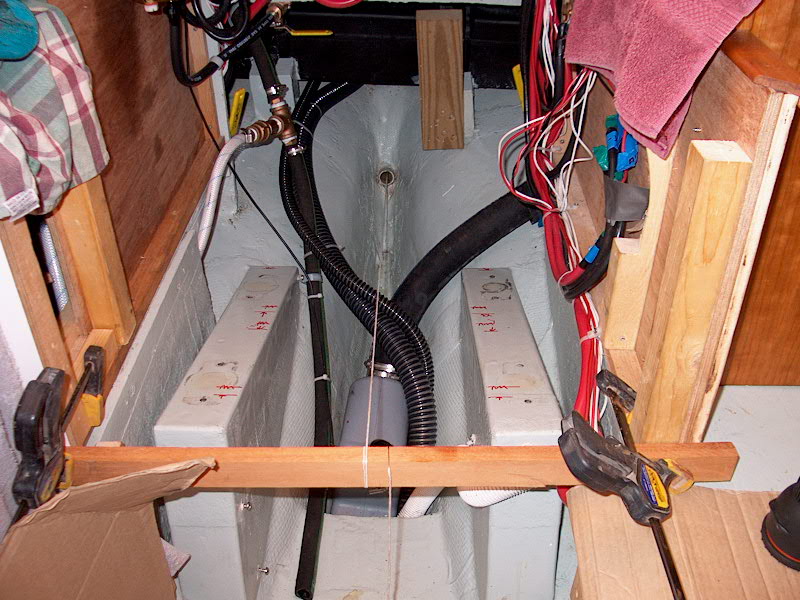

and early the day after hauling and removing the old engine, I was back on the job. The first thing to do was to rig up a

string through the center of the stern tube--the string represents the center of

the propeller shaft, which is the most critical measurement when installing an

engine. I passed a string through the tube from inside, and tied it to a

pencil, which I then taped across the exterior of the opening--attempting to get

it dead center, but I'll come back to it later to be sure. Moving back

inside, I drew the string up tight, and secured it to a board that spanned

across the front of the engine box. I moved the string and board around

until I could visually see that the string was passing through the center of the

stern tube. I went back outside and checked the pencil, and made some

small adjustments now that the string was under tension from the inside.

Then, I checked it again from the inside. Perfect. Bright

and early the day after hauling and removing the old engine, I was back on the job. The first thing to do was to rig up a

string through the center of the stern tube--the string represents the center of

the propeller shaft, which is the most critical measurement when installing an

engine. I passed a string through the tube from inside, and tied it to a

pencil, which I then taped across the exterior of the opening--attempting to get

it dead center, but I'll come back to it later to be sure. Moving back

inside, I drew the string up tight, and secured it to a board that spanned

across the front of the engine box. I moved the string and board around

until I could visually see that the string was passing through the center of the

stern tube. I went back outside and checked the pencil, and made some

small adjustments now that the string was under tension from the inside.

Then, I checked it again from the inside. Perfect.

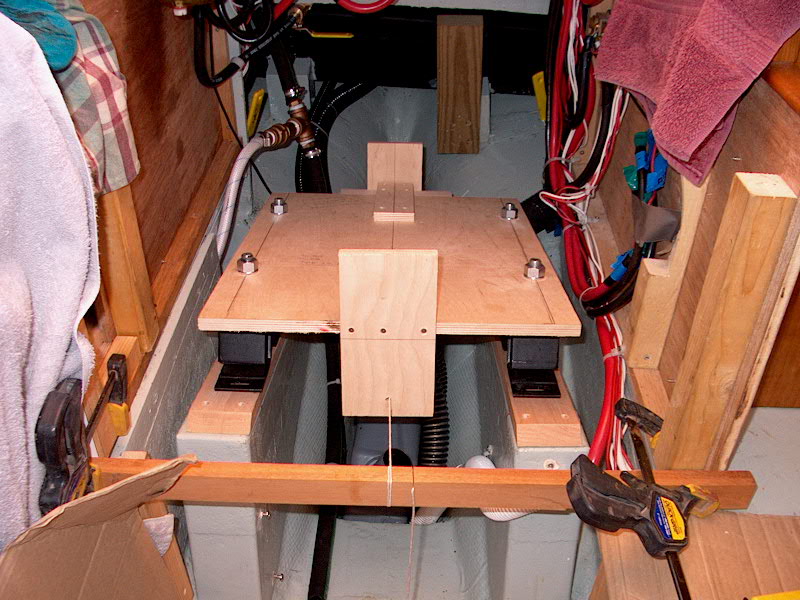

Next, I placed the engine

template on the beds, passing the string through the holes in the template

projections. Just before doing this, I adjusted the flexible mounts so

that they were approximately in the middle of their range, which would allow me

the freedom to make adjustments in any direction. Immediately, it was

obvious that my calculations were right--I'd have to raise the engine beds

somewhat. That's easy--I'm just glad I didn't have to cut them down, or

change them altogether. Raising the template a little by hand, I estimated

that 3/4" would be a bout perfect. I left the boatyard to go home and

search my scrap pile for some suitable oak to do the job. I found just

enough, and milled two pieces to 3" x 23" to fit the existing beds.

|

|

My

plan was to epoxy the boards in place, and to hold them temporarily with

screws to allow me to continue working while the epoxy set up. Plus, the

lags that secure the engine mounts will pass through the oak, further securing

it. The oak strips are really just shims--the structure of the foundation is

already in place. Transferring my marks that I made after removing the old

engine to the sides of the foundation, I sanded the paint off the tops to give

the epoxy a good surface to bond to. Then, I cleaned both surfaces with

Acetone, mixed up a thick epoxy mixture, applied it to the bottoms of the

boards, and screwed the oak pieces into place. I cleaned up the goop that

squeezed out, and I was ready to continue. My

plan was to epoxy the boards in place, and to hold them temporarily with

screws to allow me to continue working while the epoxy set up. Plus, the

lags that secure the engine mounts will pass through the oak, further securing

it. The oak strips are really just shims--the structure of the foundation is

already in place. Transferring my marks that I made after removing the old

engine to the sides of the foundation, I sanded the paint off the tops to give

the epoxy a good surface to bond to. Then, I cleaned both surfaces with

Acetone, mixed up a thick epoxy mixture, applied it to the bottoms of the

boards, and screwed the oak pieces into place. I cleaned up the goop that

squeezed out, and I was ready to continue.

|

|

Setting the alignment template back on top of the

new oak shims and lining it up with my marks, I could see that now I just had to

make some minor adjustments to the nuts on the flexible engine mounts. The

forward end was sitting a little too low, and the aft end a touch too

high. I made the appropriate adjustments, and the string came nicely into

place through the center of

each hole in the template extensions. If anything, I left the adjustment a

little high, since the manual states that the engine should compress the mounts

by about 3.5mm when it is installed. Setting the alignment template back on top of the

new oak shims and lining it up with my marks, I could see that now I just had to

make some minor adjustments to the nuts on the flexible engine mounts. The

forward end was sitting a little too low, and the aft end a touch too

high. I made the appropriate adjustments, and the string came nicely into

place through the center of

each hole in the template extensions. If anything, I left the adjustment a

little high, since the manual states that the engine should compress the mounts

by about 3.5mm when it is installed.

With my final adjustments made, I ensured that

the template was properly lined up with the fore and aft marks I made earlier

(to ensure that the existing shaft would properly mate with the new transmission

coupling) and then marked the boltholes that would secure the mounts to the

foundation. Then I removed the template and drilled pilot holes for the

lags screws that will hold the mounts in place when I install the engine.

I labeled each mount for its location as well, since the adjustments on each are

slightly different--they need to go in the proper places on the engine in order

to keep my pre-alignment perfect.

|

| Before proceeding, I reinstalled the stuffing box

and slid the shaft in from the inside--remember, the coupling is still

installed. I pushed the shaft as far aft as possible to keep it out of the

way. With that done, it was time to hoist the new engine into the

boat.

Click here to continue. |

|