|

A New Mahogany Tiller

This page was last updated

on 1 December 2003.

Click here to

jump to the newest update (July 2004) |

|

When the boat that was to become

Glissando entered our lives, she was equipped with what appeared to

be the original tiller: solid oak, relatively short, and

uninspired. I never intended to use the old tiller, and replaced

it with a store-bought tiller before launching in May 2001. It was

a quick and easy way to get a workable tiller.

The store-bought version

wasn't a perfect fit, but it was longer, higher, and more substantial

than the original oak tiller. Laminated of strips of mahogany and

ash, it was OK looking. You've all seen these things

everywhere. In general, I liked the shape and function of it, but

there was room for improvement.

Then, during the summer

of 2003, the tiller developed a bad split down the longitudinal

centerline, starting at the screwholes securing the tiller

extension. I repaired it

temporarily by wrapping fiberglass cloth around it, which was enough to

get through the remains of the season, but the handwriting was on the

wall: time for a new tiller.

|

|

With the old tiller removed, I began the

templating process in order to build a new tiller. I wanted a

somewhat different shape than the existing--a tiller that came out of

the tiller head more horizontal in attitude, but then curved up steeply

to the ultimate height before continuing forward. This design, at

least in my head, seemed to solve some clearance and use problems that

occurred with the old, basic-arch design, and would provide a horizontal

section at the end where the hand typically grips.

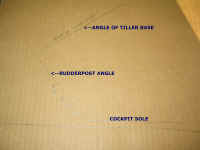

To

begin, I drew a basic mockup of the cockpit sole, rudderpost, and tiller

angle, using a bevel gauge to imitate the actual angles on the boat and

transferring the measurements to a sheet of cardboard I had lying

around. Then, using the old tiller as a sort of guideline, I drew

up a voluptuous new shape on the cardboard, using a flexible plastic

spline and architect's ducks. I cut the new tiller template out of

the cardboard, and "installed" it in the tiller head to see

how it worked in the cockpit. To

begin, I drew a basic mockup of the cockpit sole, rudderpost, and tiller

angle, using a bevel gauge to imitate the actual angles on the boat and

transferring the measurements to a sheet of cardboard I had lying

around. Then, using the old tiller as a sort of guideline, I drew

up a voluptuous new shape on the cardboard, using a flexible plastic

spline and architect's ducks. I cut the new tiller template out of

the cardboard, and "installed" it in the tiller head to see

how it worked in the cockpit.

|

|

|

Despite

the floppy cardboard, I could get a sense of the new shape, and saw that

there was a need for a few changes. The forward part of the

template drooped down farther than I liked, and the after portion, above

the "S" curve, was also a bit lower than I had hoped.

But the arch seemed generally OK, though the curve was severe, and the

tiller cleared the seats easily when turned, without even needing to

lift the tiller at all. Despite

the floppy cardboard, I could get a sense of the new shape, and saw that

there was a need for a few changes. The forward part of the

template drooped down farther than I liked, and the after portion, above

the "S" curve, was also a bit lower than I had hoped.

But the arch seemed generally OK, though the curve was severe, and the

tiller cleared the seats easily when turned, without even needing to

lift the tiller at all. |

|

With

version one in the bag, I decided to refine the general design and

address the minor changes needed. Instead of cardboard, I used a

sheet of 1/4" lauan plywood to create a new template, making a few

modifications to the shape of the original cardboard template. I

decided I wanted the overall height of the tiller end to remain about

the same as the existing tiller (which is about 24" above the

cockpit sole), so that meant raising the end (according to the cardboard

template) by a couple inches. I cut the new template out with a

jigsaw, and tried it out in the cockpit. With

version one in the bag, I decided to refine the general design and

address the minor changes needed. Instead of cardboard, I used a

sheet of 1/4" lauan plywood to create a new template, making a few

modifications to the shape of the original cardboard template. I

decided I wanted the overall height of the tiller end to remain about

the same as the existing tiller (which is about 24" above the

cockpit sole), so that meant raising the end (according to the cardboard

template) by a couple inches. I cut the new template out with a

jigsaw, and tried it out in the cockpit.

|

|

The

lines and curves were a bit unfair, and the overall shape definitely

needed some refining, but this was much more of the shape I had been

envisioning all along. It looks a little funny and awkward as it

stands, since the tiller really doesn't follow a smooth line out of the

tiller head. Obviously, any final version will be much more

refined and will hopefully flow more smoothly. For the time being,

the point is to test basic shapes and designs, with refinement to come

once a final candidate is chosen. The

lines and curves were a bit unfair, and the overall shape definitely

needed some refining, but this was much more of the shape I had been

envisioning all along. It looks a little funny and awkward as it

stands, since the tiller really doesn't follow a smooth line out of the

tiller head. Obviously, any final version will be much more

refined and will hopefully flow more smoothly. For the time being,

the point is to test basic shapes and designs, with refinement to come

once a final candidate is chosen.

|

|

I

tested the new design out and was pleased to see that it cleared my

knees when I sat in a variety of locations, and, as with the original

cardboard template, cleared the cockpit seats nicely. These were

two of the main objectives for the new design. It was also at a

comfortable height for straddling while standing, which I like to do

when powering, or sailing downwind (or upwind in light airs sometimes). I

tested the new design out and was pleased to see that it cleared my

knees when I sat in a variety of locations, and, as with the original

cardboard template, cleared the cockpit seats nicely. These were

two of the main objectives for the new design. It was also at a

comfortable height for straddling while standing, which I like to do

when powering, or sailing downwind (or upwind in light airs sometimes).

|

This

picture shows the evolution of the current design...though this design

is not yet cast in stone, or even close to. Starting with the

existing tiller, the major change to the cardboard template is obvious,

with its radically different shape and philosophy. The

evolutionary changes from the cardboard to the lauan template are also

apparent. Note that the three shapes shown here aren't necessarily

properly angled according to how the rudderpost exits the cockpit, so

please forgive any slight inconsistencies in their appearance or apparent

shape. The lauan template at the top of the photo actually sits

the same height above the cockpit sole at its forward (handle) end as

the original tiller at the bottom, and extends about as far

forward. It's just the way in which it reaches that height and

length that is different. This

picture shows the evolution of the current design...though this design

is not yet cast in stone, or even close to. Starting with the

existing tiller, the major change to the cardboard template is obvious,

with its radically different shape and philosophy. The

evolutionary changes from the cardboard to the lauan template are also

apparent. Note that the three shapes shown here aren't necessarily

properly angled according to how the rudderpost exits the cockpit, so

please forgive any slight inconsistencies in their appearance or apparent

shape. The lauan template at the top of the photo actually sits

the same height above the cockpit sole at its forward (handle) end as

the original tiller at the bottom, and extends about as far

forward. It's just the way in which it reaches that height and

length that is different. |

|

After

a few days' reflection, and some discussion with Nathan (Dasein 668),

who also wanted a new tiller, I decided some modification was in

order. The funky new shape, while close to the ultimate goal, just

lacked the proper aesthetic flow. The solution was to more closely

emulate my existing tiller's shape near the butt end, and to smoothly

merge that shape with the new templated shape, eliminating some of the abrupt

bend in the template that simply didn't look good. The upper

portion of the curve remained in the same place, allowing for excellent

knee and cockpit seat clearance (one of the significant design goals),

but sacrificed a small amount of the lowness of the butt end in favor of

improved aesthetics--and, as I was soon to discover, improved

possibility of successful construction. After

a few days' reflection, and some discussion with Nathan (Dasein 668),

who also wanted a new tiller, I decided some modification was in

order. The funky new shape, while close to the ultimate goal, just

lacked the proper aesthetic flow. The solution was to more closely

emulate my existing tiller's shape near the butt end, and to smoothly

merge that shape with the new templated shape, eliminating some of the abrupt

bend in the template that simply didn't look good. The upper

portion of the curve remained in the same place, allowing for excellent

knee and cockpit seat clearance (one of the significant design goals),

but sacrificed a small amount of the lowness of the butt end in favor of

improved aesthetics--and, as I was soon to discover, improved

possibility of successful construction.

|

|

Satisfied

with the lauan template of the new shape, I decided to build a more

full-sized mockup with which I could actually test the operation of the

new tiller. From a scrap piece of 2x10 lumber, I jigsawed the

tiller template, and installed it to the bronze tiller head for a

test. Both of us were pleased with the looks and performance of

the new shape, so we agreed to go ahead with its construction. Satisfied

with the lauan template of the new shape, I decided to build a more

full-sized mockup with which I could actually test the operation of the

new tiller. From a scrap piece of 2x10 lumber, I jigsawed the

tiller template, and installed it to the bronze tiller head for a

test. Both of us were pleased with the looks and performance of

the new shape, so we agreed to go ahead with its construction.

The photo below shows the

full evolution of the tiller shape, from the existing (and generally

satisfactory) stock tiller to the ultimate shape of the new design. |

|

|

|

I planned to make the new tillers out laminated strips of mahogany,

deciding against adding contrasting strips as is common in stock

tillers. I cut enough 1/4" thick strips for the job from a

large piece of 8/4 mahogany that I had on hand, a piece with excellent

color and overall quality, and prepared to build a laminating jig with

which to glue up the tillers.

Presently, though, I had

a problem. It seemed the designed curve was too tight for cold

molding of the mahogany strips. As part of the mold construction,

I used a strip of the mahogany to help me create a fair, smooth curve

between clamping block locations. After I had installed several of

the blocks, I clamped on a piece of the mahogany, but found that I

couldn't make the two-direction bend without splitting the wood. I

wasn't sure if the problem was a factor of the wood simply not being

bendy enough, the jig being too sharp and hard a surface against which

to bend, or a combination of the two. The difficulty arose because

of the requirement for the wood to bend in two directions over a

relatively short span; bending the strips through either of the two

curves would work, but forcing them first into one curve, then almost

immediately into a completely opposite curve, proved to be too

difficult--at least with dry strips.

Discouraged, but far from

beaten, I put the jig and strips aside for a while, and looked into

building a steam box in which to steam the wood strips to make them more

pliable. Steaming the wood was but one possible option; changing

the format of the jig might also work.

Click

here to continue> |

|