|

Anchoring Setup and Ground Tackle (Page 4)

This page was last updated on June 2, 2002

35#

CQR 33# Bruce/Claw

20# Danforth

13#

Danforth

Marking

the Anchor Rodes Anchor Rode

Storage/Chain Pipes |

|

Marking

the Anchor Rodes

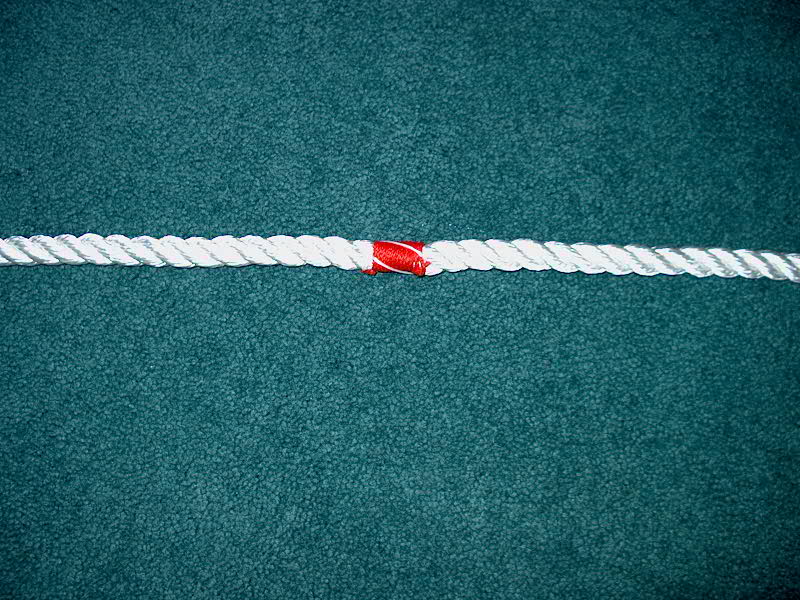

It's useful, if not essential, to

know how much anchor rode you have out at any time. This means that the

rode must be marked. Most people buy those little plastic strips from the

marine store and install them through the strands of their anchor line--I've

used them myself. The problem with these is that they tend to rip off and

fail in a short time. A better solution is called for.

In Cost Conscious Cruiser,

by Lin & Larry Pardey, I read about their own solutions to marking the

anchor rode. They have a good solution for both all chain and nylon

rodes. My rodes are mostly nylon, so I thought I'd try their marking

solution. I modified the idea slightly for reasons that I'll discuss

below.

Their idea is to use some strong

thread--they used a polyester twine used for mending fishing nets--and create

tight whippings around the line in a predictable, and easy to remember, pattern

to instantly identify how much line is out. The whippings, being small and

tight, hold up well, even when a windlass is used. We don't have windlass

at this time, but the idea still made sense. Because all of their rodes

are the same length, they created a system where the number of markings increase

up to the center of the rode, and then decrease again as it continues--allowing

the rode to be end-for-ended to spread wear, and the marking system would remain

the same.

We have several different-length

rodes, so I couldn't come up with a system to keep the markings consistent from

end to end on all of

them. Therefore, I decided to just keep increasing the number of whippings

for each marking as I went along--this means that there will end up being a lot

of marks at some lengths, but the only downside to this is the time needed to

create all the whippings. I started the job in February, when the Olympics

were on TV. It's pretty mindless work, so this was the perfect time to do

it. I sat on the couch in the living room and did my little sewing

project--it was even kind of fun! It doesn't really take that long, once

you get used to it.. To prevent the number of marks from

getting too ridiculous I decided to use a single wrap of a second color (red) to

signify (and replace) five blue markings. This means that I can

essentially start over every four marks. See the chart below to see how

this works.

Like the Pardeys, I decided to

mark the rodes every 30' of length. The marking system is below:

-

30 feet: One blue

mark

-

60 feet: Two blue

marks

-

90 feet: Three

blue marks

-

120 feet: Four

blue marks

-

150 feet: One red mark

-

180 feet: One red mark

and one blue mark

-

210 feet: One red mark

and two blue marks

-

240 feet: One red mark

and three blue marks

-

270 feet: One red mark

and four blue marks

-

300 feet: Two red marks

-

330 feet: Two red marks

and one blue mark

-

And so on....(if required)

|

|

So, on any given rode, all you

need to do to determine how much is out is multiply the number of marks by

30--easy to do. An added advantage is that the markings are apparent just

by feel, so they can be detected in the dark even without a light if need

be.

I bought a spool of red and a

spool of bright blue

polyester cording called heading twine. (Hamilton

Marine or other fishing supply house) It's very strong, and the bright

color forms an excellent contrast with the white rope. This material is

perhaps a little thick, but it doesn't matter. I debated using a thinner

material they had at the store (black), but decided I liked the bright color of

the heading twine. They had several colors in stock.

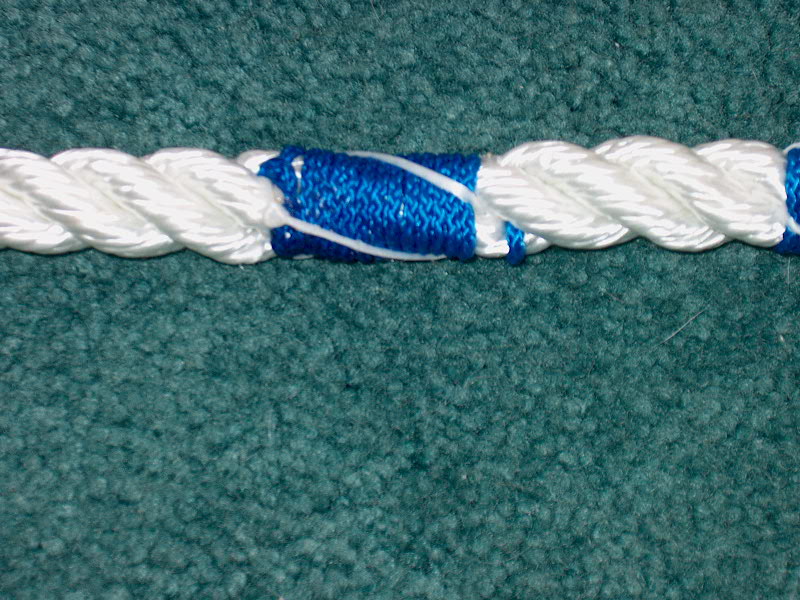

To

make each mark, I cut a length of the heading twine and began by tying it to one

strand of the anchor rode (3-strand nylon). It's easy to separate the

twist of the line for this. I pulled the simple knot tight, and then

wrapped the line tightly around the rode until I had about 3/4"

covered. Then, I completed the wrapping by tying the twine to itself and

again through the strands of the rode. To help seal the knots, I used my

small torch to slightly melt the ends and make the knots permanent. I

repeated this process for each whipping, spacing them about 1-1/2" or so

apart. The line is marked every 30 feet. To

make each mark, I cut a length of the heading twine and began by tying it to one

strand of the anchor rode (3-strand nylon). It's easy to separate the

twist of the line for this. I pulled the simple knot tight, and then

wrapped the line tightly around the rode until I had about 3/4"

covered. Then, I completed the wrapping by tying the twine to itself and

again through the strands of the rode. To help seal the knots, I used my

small torch to slightly melt the ends and make the knots permanent. I

repeated this process for each whipping, spacing them about 1-1/2" or so

apart. The line is marked every 30 feet.

This would probably be enough,

but I went a step further and whipped the marks with some regular white waxed

sail thread. I used a large needle to push the thread through the strands

of the rode, following the twist of the line, and pulling it tight. This

should really secure the marks in place. The heading twine was too thick

for this purpose--that would be one advantage of using the thinner black nylon

stuff I had considered. After tying off the thread, I melted the knots

with my torch and also give the whole whipping a slight bit of heat to sort of

seal the thread and twine together.

|

|

I

found that the polyester twins is very hard on the hands when pulling it

tight. But, in one night--not working the whole time by any stretch--I

marked one of my rodes up to 150' of length. That's a total of 15

whippings. You

can click the picture, left, for a larger view. I

found that the polyester twins is very hard on the hands when pulling it

tight. But, in one night--not working the whole time by any stretch--I

marked one of my rodes up to 150' of length. That's a total of 15

whippings. You

can click the picture, left, for a larger view.

|

|

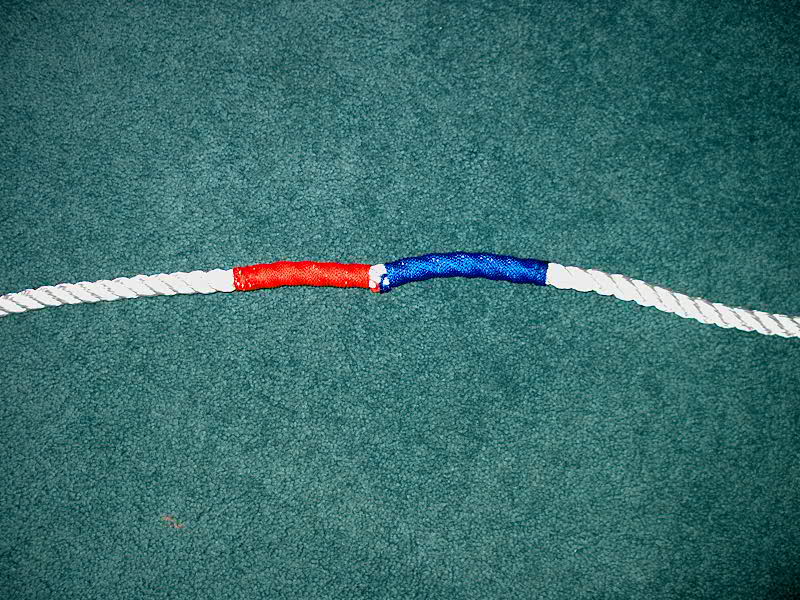

At

the last marking on each line--usually about 30 feet or so from the bitter

end--I made some unmistakable marks on the line so that it would be obvious that

the end of the line was very near. To do this, I wrapped about  3-4"

of the line with red twine, and a further 3-4" with the blue twine.

This creates a mark that is extremely easy to see and will not be mistaken for

anything else. When this mark comes up through the deck pipe, it's time to

cleat off that anchor rode for good. Then, I added a traditional

whipping to the very end of the line using the white waxed sail thread, just to

supplement the melted end as was supplied by the manufacturer. 3-4"

of the line with red twine, and a further 3-4" with the blue twine.

This creates a mark that is extremely easy to see and will not be mistaken for

anything else. When this mark comes up through the deck pipe, it's time to

cleat off that anchor rode for good. Then, I added a traditional

whipping to the very end of the line using the white waxed sail thread, just to

supplement the melted end as was supplied by the manufacturer.

|

|

Anchor

Rode Storage--Fore and Aft

The Triton is blessed with a huge

chain locker forward of the vee berth. There's plenty of room here for two

substantial rodes. Because I installed two anchors at the bow--two anchors

that I want to both be ready to drop at any time--I needed to partition the

chain locker so that the two rodes would stay separate from each other.

The photo shows the chain locker before beginning the divider project--huge and

wide open. The Triton is blessed with a huge

chain locker forward of the vee berth. There's plenty of room here for two

substantial rodes. Because I installed two anchors at the bow--two anchors

that I want to both be ready to drop at any time--I needed to partition the

chain locker so that the two rodes would stay separate from each other.

The photo shows the chain locker before beginning the divider project--huge and

wide open.

To create the simple divider, I

took a few measurements of the space in the locker and cut a piece of

3/4"plywood to fit. It doesn't have to be perfect--it's hidden and is

only a rope divider. Once I was satisfied with the way my piece was

fitting, I coated the entire thing in unthickened epoxy resin to seal it.

When the epoxy cured, I scrubbed off the amine blush with water and a

Scotch-Brite pad, and sanded it to give it tooth for future paint.

|

|

With

a warm day in February, I decided to go ahead and install the divider in

place. I mixed up some thick epoxy (using 406 colloidal silica). I

spread a heavy bead of epoxy along the bottom edge of the locker (in the crease)

and on the bottom, vertical edge of the stem reinforcement. I also applied

some to the forward side of the chainlocker bulkhead where the divider would

touch. Then, I pressed the divider into this goop, and spread any

remaining around to fill gaps and create a small fillet. I left it to

cure. The new divider will eventually be painted to match. With

a warm day in February, I decided to go ahead and install the divider in

place. I mixed up some thick epoxy (using 406 colloidal silica). I

spread a heavy bead of epoxy along the bottom edge of the locker (in the crease)

and on the bottom, vertical edge of the stem reinforcement. I also applied

some to the forward side of the chainlocker bulkhead where the divider would

touch. Then, I pressed the divider into this goop, and spread any

remaining around to fill gaps and create a small fillet. I left it to

cure. The new divider will eventually be painted to match.

A related project is the covering

and finishing of the forward chain locker bulkhead. Please click here

to view that project.

CQR RODE: It may not be the most elegant

solution, but I ran the anchor rode for the CQR anchor through the existing

bronze ventilator on the foredeck. Perhaps I'll install a proper chain

pipe someday, but this works for the moment. For stormy conditions, there

are a couple options to seal off this ventilator: stuff it with clay (or silly

putty!); spray in some canned foam; or install a canvas cover over the entire

thing. Most of the time, for the type of sailing we do so far, we can

leave the ventilator open without a problem.

CLAW RODE: For the second anchor,

I installed a bronze chain pipe made by ABI. It features a removable cover

(with slots for chain and rode) and a large opening (3-1/2") to allow the

rode and chain to easily pass through. None of this stuffing a line

through a tiny hole, an exercise in maximum frustration. Also, I didn't

want one of those oval chromed ones that are so common.

The first thing I did after

getting the new chain pipe was to spray a number of coats of clear lacquer over

the entire thing to prevent it from tarnishing. I found that this worked

well for my exterior bronze last season, although the cold during the winter

seemed to cause the lacquer to shrink and peel off. I'll deal with this

later.

I installed the chain pipe on the

foredeck to allow the second anchor rode to be passed into the chain locker

beneath. Please click here to read

how.

STERN ANCHOR RODE:

For the stern anchor, I think

I'll install another one of those round deck pipes in the poop deck, and create

a storage area for the line in there. This project is complete Click

here.

|

|