|

Chain Locker Bulkhead (Page 2)

This page was last updated on 3

March 2002

|

|

Once

the glued up chain locker door had cured overnight, I removed the clamps and

prepared for a variety of milling operations. The first thing to do was to

sand off the epoxy that had squeezed out on the back side. Next, I

milled a 3/8" x 3'8" rabbet on the back side all the way around.

This lets the door overlap the cutout in the bulkhead for a clean

installation. I used a stacked dado head in my table saw for this

cut. When that was complete, I replaced the dado with the regular table

saw blade and, in two passes around the perimeter, milled an 11/64" wide

by 3/16" deep groove all the way around for the reed spline that is

used to hold the caning in place in the center. Once

the glued up chain locker door had cured overnight, I removed the clamps and

prepared for a variety of milling operations. The first thing to do was to

sand off the epoxy that had squeezed out on the back side. Next, I

milled a 3/8" x 3'8" rabbet on the back side all the way around.

This lets the door overlap the cutout in the bulkhead for a clean

installation. I used a stacked dado head in my table saw for this

cut. When that was complete, I replaced the dado with the regular table

saw blade and, in two passes around the perimeter, milled an 11/64" wide

by 3/16" deep groove all the way around for the reed spline that is

used to hold the caning in place in the center.

My

final milling operation was to cut 1/4" roundovers (with a router table) on

all outside edges of the door, as well as on the face side of the space in the

middle. Then, I spent some time sanding the hole frame smooth to 220

grit. Then, adding the door to a collection of small mahogany pieces--and

the new mahogany bulkhead--I prepared to apply several coats of tung oil.

This is the same finish I used on other mahogany trim on the boat, and it works

extremely well. I just wipe it on, and can do several coats in a short

time. 5-6 coats provides a hard, soft-gloss finish that looks great. My

final milling operation was to cut 1/4" roundovers (with a router table) on

all outside edges of the door, as well as on the face side of the space in the

middle. Then, I spent some time sanding the hole frame smooth to 220

grit. Then, adding the door to a collection of small mahogany pieces--and

the new mahogany bulkhead--I prepared to apply several coats of tung oil.

This is the same finish I used on other mahogany trim on the boat, and it works

extremely well. I just wipe it on, and can do several coats in a short

time. 5-6 coats provides a hard, soft-gloss finish that looks great.

When the finish was complete, I proceeded with

the caning. The process is described step-by-step below.

|

|

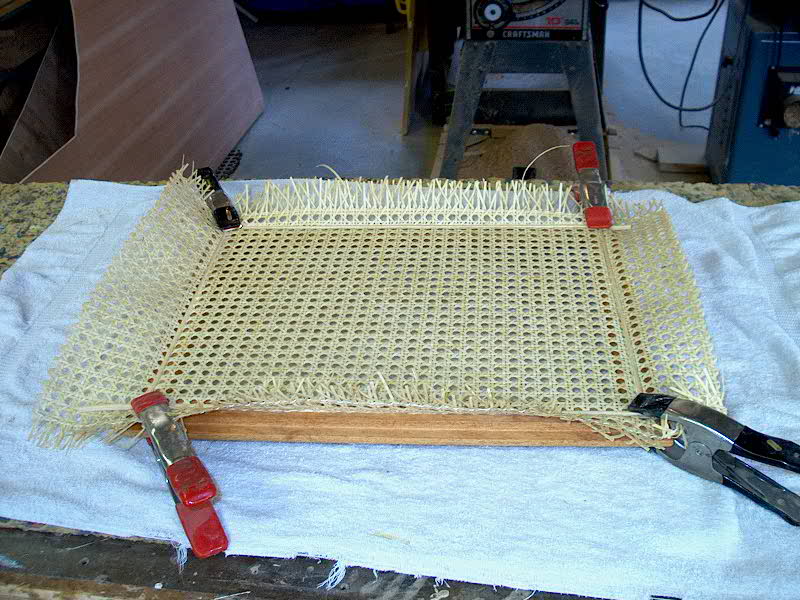

First, I cut a piece of pre-woven cane to

overlap the opening by a couple inches on all sides. Then, I submerged it

in a bucket of warm water to soak for a while. (15-30 minutes). The

reason for doing this is that the caning will expand when wet, and when it's

tightly splined in place on the door, it will shrink as it dries, leaving a

drum-tight surface.

Next,

I prepared for installation by cutting four pieces of reed spline to

approximately the right length for each of the four sides. The two long

sides can extend beyond the groove during installation, but the short sides'

reed had to be cut to fit between. Once this was done, and the caning had

soaked long enough, I shook the extra water off the caning, and went to

work. Laying it out over the door, I used my custom caning-insertion tool

(a cheap plastic schoolboy protractor) to press the damp caning into the four

grooves, ensuring that the weave remained straight and tight as I did so.

A small amount of looseness is OK, as it will shrink up as it dries--but the

caning should be as tight as possible at this stage. Next,

I prepared for installation by cutting four pieces of reed spline to

approximately the right length for each of the four sides. The two long

sides can extend beyond the groove during installation, but the short sides'

reed had to be cut to fit between. Once this was done, and the caning had

soaked long enough, I shook the extra water off the caning, and went to

work. Laying it out over the door, I used my custom caning-insertion tool

(a cheap plastic schoolboy protractor) to press the damp caning into the four

grooves, ensuring that the weave remained straight and tight as I did so.

A small amount of looseness is OK, as it will shrink up as it dries--but the

caning should be as tight as possible at this stage.

|

|

Next,

one edge at a time, I ran a bead of yellow glue in each groove, and inserted the

reed spline, hammering it into place as necessary with my rubber mallet. I

did this for each edge in succession. Next,

one edge at a time, I ran a bead of yellow glue in each groove, and inserted the

reed spline, hammering it into place as necessary with my rubber mallet. I

did this for each edge in succession.

To help hold the corners of the splines in

place (they tend to want to pop out), I clamped each corner with a spring clamp

to hold things in place. I let the glue dry for several hours at least

before continuing.

|

|

After I let the glue dry, I trimmed the excess

caning and spline with a sharp utility knife, cutting just outside the spline

all around. This completed the construction of the door. Next, I

installed two brass 3/8" overlay cabinet hinges on one side, and a brass

knob on the other side to match the rest of the doors in the boat. Then, I

installed the door on the new bulkhead (still in the shop), along with a brass

door catch.

Bringing the whole assembly up to the boat, I

installed the previously test-fit bulkhead permanently in place. It serves

no structural purpose, so I attached it to the existing partial bulkhead and new

overhead plywood beam with a series of screws from the back (chain locker)

side.

|

|

With Door Open (Sorry--Blurry!)

With cushions and new bookshelf

installed

|

|