|

Spring 2007

Maintenance and Preparations |

The

newest updates are at the top of the page; please

click here to go the bottom of the page

to begin at the--well--beginning.

|

June 4 & 6, 2007:

Launching

Bad weather on Monday, June 4

caused me to cancel the launching--but not until we reached

the public ramp in Rockland and could truly see the

conditions. What a pain. Fortunately, I was able

to reschedule for Wednesday, June 6.

Please

click here to read all about

the launching.

|

June 2, 2007

After a couple weeks where I didn't really do that

much on the boat--since she was more or less ready for

launch--I spent a couple days taking care of the final

pre-launch projects, such as loading cushions, sails, and

other gear on board, installing the anchor rollers, anchor

rodes, and anchors, and taking care of a few minor chores.

Then, on Saturday I rigged up

the mast with its halyards and stays, a process that took

several hours including securing the mast to the pulpits for

transport on Monday. I also washed the decks one more

time to rid them of grime from the past month.

With that, the boat was

ready for launch. All I had to do was put the boom on

deck. |

|

|

May 11, 2007

Last week, I rescheduled my launching date for June 4--not

because I wanted or needed to go in later, but because I

came to the conclusion that I really wanted to stick with

Steve for my boat moving, and just wasn't comfortable with

the other arrangements I had made.

The boat is basically ready

to go in now, though I still have a short list of projects

that I hope--and expect--to get done over the next few

weeks. The late launch date is truly relaxing and

luxurious, in a way. And, frankly, sailing season

doesn't get going up here till June anyway, as much as it'd

be nice to extend it. But early launches tend to lead

to disappointment, non-use, and, all too often, nasty spring

storms to worry about. So while I am still bothered by

the (gasp!) June launching date on some level, it is

actually working out extremely nicely for me this year,

particularly with so much going on at work and with the

house, and with the whole new boat relocation thing

happening.

|

May 8, 2007

Contain your excitement: today, I varnished the other

side of the coamings, and I don't even have pictures to show

you!

|

May 6, 2007

Over the weekend, I installed the stanchions and lifelines,

and fabricated new chainplate deck covers to replace the

old, which were a few years old and needed rebedding.

Since commercially available plates don't fit in the space I

have, I have always built simple 1/4" thick sections of

mahogany with slots cut out for the chainplates. After

removing the old ones, I bedded the new ones with a heavy

glop of polysulfide.

Sunday, I decided to paint the

bottom and get that out of the way. In a few days,

I'll move the stands and paint the areas that I couldn't get

during the first round. |

|

|

May 1, 2007

Last weekend, I spent part of Saturday afternoon working on

the engine--first an overall inspection, then reassembly of

the water pump, and finally a test run. Not

unexpectedly--yet still somehow surprisingly--the engine

started immediately, as if I had only shut it down a few

minutes earlier rather than a year and a half ago. The

Yanmar is always a champ. I ran the engine for some

minutes, confirmed that the charging system was working

properly, and enjoyed the moment.

Sunday, I carted load after

load of gear down from the attic so that it would be readily

accessible for loading and inspection. I also

reorganized my fastener box, as I had picked up a new

storage system to replace the heavy, unwieldy, and

inefficient large tackle box that I had used before.

The old box, still containing larger fasteners and other

random spare parts, would need to remain on board, but now

the basic screws and bolts that I'd typically need for

maintenance or repairs would be better organized for easier

use.

Tuesday, I sanded down the

coamings, lazarette hatch, and tiller, and applied a coat of

varnish to all (one side of the coamings only at this time,

of course). All were in good condition and required

only maintenance coats. After I have a chance to apply

a coat of new varnish to the other side of the coamings in a

few days, I'll reinstall these pieces on the boat where they

belong. |

|

|

April 27, 2007

The great stretch of weather continued through Wednesday,

allowing me to get 5 coats of varnish on the toerails.

I needed to take down the staging Wednesday afternoon for

use in

the shop again after my short break, but at least I

now had enough varnish on the toerails to take the pressure

off. With luck, I'll manage a few more coats sometime

between now and launching, but there's enough to last the

season if it absolutely had to.

There's still varnish work

required on deck, in areas that I can reach without staging.

And there's a host of engine maintenance tasks ahead,

including fuel and oil filters and a careful inspection,

since the engine hasn't run since September '05.

Launching date is May 29,

the day after Memorial Day. We'll see how that all

goes, with an untested hauler and a new boatyard for mast

stepping. |

|

|

April 23, 2007

I had many errands to run today, taking advantage of one of

the few days off I allow myself during the week, thanks to a

brief period of downtime before my next work project began

later in the week.

Among my errands was a trip to Ed's Batteries to replace my

aged trio of boat batteries. The two Trojan T-105s and

single Trojan starting battery had served me well since

2001, but I had noticed some decrease in performance during

our last sailing season in 2005, and last year, 2006, was

the kiss of death for the batteries; I had hooked them up

and left them aboard during the summer to allow the bilge

pump to drain any rainwater, but never paid them much

attention, and they wouldn't take a charge now.

I replaced them in kind

with a new pair of T105s and a new Trojan 24SM850 starting

battery. The price on the T105s had increased

substantially since I bought the first pair.

When I got back to the boat

late in the morning, I installed the new batteries--always a

fun chore on this boat, given the limited access.

Then, I sanded the toerails and sea hood top again (the sea

hood sides were in good condition and needed only

maintenance coats, which I'll apply once I build up several

base coats on the top) and applied more varnish. It

was extremely warm today--in the 80s, which set records

across the state. Too hot for varnish, really, but

since they were base coats I didn't worry too much about it.

I took these photos early

the next morning after a brief rain shower. |

|

|

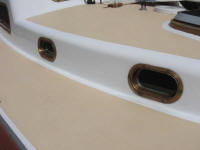

April 22, 2007

With clear skies yet again and more warm temperatures, I

decided this morning to get the bronze port frames

refinished and over with--a more or less annual ritual,

though I didn't touch them during last year's "season of

neglect", and they were in surprisingly good condition this

spring--though with flaking lacquer in some areas they

clearly needed to be refinished. These two photos

showing the beginning condition are pretty poor...sorry. |

|

|

| As usual, the preparation

and masking took far more time than the actual work. I

began by masking off the inside and outside of all the

frames, after which I sanded them with 80 and 220

grits to remove flaking lacquer and clean them up a bit.

As usual, I didn't obsess over this; I like the old patina,

and have never spent huge amounts of time on prep. I

go for the aged, yet bright, bronze appearance.

Next came my favorite

part--and by far the most annoying and time-consuming:

applying masking paper around all the ports so that the

spray lacquer wouldn't coat the adjacent surfaces.

This took forever...plus, I don't get the newspaper anymore,

and therefore had little in the way of material to use for

the purpose. I began using paper that had been used as

packing material in some boxes I had recently received, but

the paper was in poor shape and tore easily--very

frustrating. Then, I happened upon a large roll of red rosin

paper left over from the house construction, and this worked

well for the remaining ports--although it was far heavier

than required for the job.

With all the ports finally

masked off--I rushed to try and beat the wind--I applied

several coats of exterior spray lacquer to all the ports.

At this time, I only did the eight ports I could reach from

the staging; the two forward-facing ports in the saloon

could wait till later. But I had a limited amount of

time before I'd need the staging back in the shop for my

next work project, so I concentrated for now only on

those areas for which I truly needed the staging. |

|

|

| Once the lacquer was dry,

I sanded the toerails with 320 grit to prepare them for more

varnish. Then, I stripped the top of the sea hood,

using first the carbide scraper and then a DA sander with

120 grit. The loose and flaked varnish came off

easily, of course, but the remaining varnish--probably 15-20

coats' worth--was surprisingly difficult to remove. It

was a foregone conclusion that the mahogany plywood veneer

forming the top of the sea hood would probably be

compromised during this process, since there were already a

few areas near the edge where I had sanded a little too much

during the original construction. The top was in such

poor condition that I figured I'd do what I could, and hope

for the best.

I ended up with a few thin

spots in the veneer, but there wasn't much I could do about

that. I hoped the overall effect would be minimal in

the end, but I was already mulling over ideas for redoing

the top of the sea hood without needing to rebuild the whole

thing. That would come later, though.

It was warm in the sun, and

the first coat of thin varnish I applied to the sea hood

dried quickly, so I applied a second coat later in the day.

Then, I applied the second coat to the toerails.

|

April 21, 2007

The weather was gorgeous, and unseasonably warm, and I got

right to work on the toerails this morning. The

toerails--particularly their top, horizontal edges--were in

horrible condition, with the varnish severely crazed and

worn away, and clearly my only route was to strip them

completely. IN addition, some of the other brightwork

on board was in similarly poor condition, particularly the

sea hood top (which had been declining for the past couple

seasons anyway). But overall, the toerails represented

the most work.Using

a carbide scraper, I scraped off the varnish from the top of

the toerails and from the inside portions as well, which

were also suffering from neglect and showed many areas where

water had gotten behind the varnish, lifting it in sheets.

The exterior portion of the rails, however, were still in

sound condition, and I didn't bother stripping them to bare

wood, choosing instead to simply sand them thoroughly. |

|

|

| It was amazing to see how

one year of neglectful maintenance can begin ruining a boat.

With no time to spare last year, I didn't do anything on the

boat at all, and things had really gone to seed. It

was depressing, but I was energized to start the restoration

work. Once I had

stripped off the varnish with the scraper--which went quite

easily for the most part--I sanded the toerails with 80,

120, and 220 grits, using a sanding block where possible and

finishing with hand sandpaper for the rounded edges and

tight spots. I was pleased to find that the rails

cleaned up nicely, with no staining. |

|

|

| Next, I masked off the

deck and the brass rubrail, and applied the first coat of

varnish to the bare wood, using a thinned-down mixture to

best allow it to soak in. And thus began a long

process of building up as many coats as I could during the

unpredictable spring weather. |

|

|

April 20, 2007

Although my decision to not put the boat in the water last

season was the right one, given the amount of time I spent

building our new house, it was still difficult to go a full

year without the boat, and I was starting to really look

forward to this season's boating.

Because of travel plans, we

pulled the boat early at the end of the 2005

season--September 9, in fact. So it had been a long

time since she was in the water--by the time we reach our

scheduled launch date of May 29 this year, it will be 627

days.

April didn't work out well

at all for boats, since we had two late-season snowstorms

(14" and 6") during the first two weeks of the month,

followed a week later by the so-called "Patriot's Day" or

"Tax Day" northeaster, which brought high winds and heavy

rain.

So, much later than usual,

I finally managed to uncover the boat today. It was

pleasantly warm, and I pulled the cover off early in the

morning before the wind had time to pick up. Later in

the day, I removed the framework and chafe gear, as well as

the cockpit coamings so that I could refinish them inside.

Fortunately, the coamings were still in good condition and

required only maintenance coats of varnish. |

|

|

| First and foremost on my

work list for the spring was a substantial bath: both

above and belowdecks. I had washed the boat last

September before putting on the cover--she was filthy then

after her long summer of non-use--but winter is always tough

on the boat, and before I could do anything else I had to

start with a clean canvas. So I scrubbed the decks and

hull, and then cleaned up below, cleaning all the

countertops, woodwork, and lockers. Much better.

With that done, I set up some

staging around the boat so that I could get to work on the

most important job for the spring: refinishing the

toerails (and other brightwork. |

|

|

|

| |

|