|

Post-Storm Log: 5/26/05

|

Shortly after launching on the 18th, the weather forecast went downhill.

By late Friday, they were predicting some rainy, windy weather over the

weekend, so I went to the boat to prepare. I moved the CQR anchor

off the roller and down into the cabin, and made sure the boat was

otherwise safe and sound.The winds

didn't really materialize as they had predicted over the weekend, and I

felt I had over-prepared. Better safe than sorry. Even

Monday, though it was nasty, raining, and somewhat breezy from the

northeast, wasn't too bad, but the lousy forecast continued right into

the week.

Monday evening, however, massive wind

gusts rocked the house--it just sounded bad. There was nothing I

could do at the time, but first thing Tuesday morning I was down at the

waterfront. |

The

first thing I noticed, to my immense relief, was that Glissando was

still on the mooring. However, I immediately noticed that things

must have been very bad: the docks at PYC were all out of place,

and the gangway to the floats was broken away and submerged nearby.

Later, I found out that several boats had broken loose overnight and

gone ashore. The

first thing I noticed, to my immense relief, was that Glissando was

still on the mooring. However, I immediately noticed that things

must have been very bad: the docks at PYC were all out of place,

and the gangway to the floats was broken away and submerged nearby.

Later, I found out that several boats had broken loose overnight and

gone ashore. |

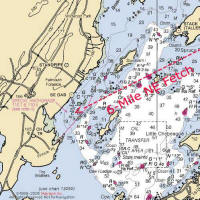

The

anchorage at Falmouth contains 1300 moorings, but is in a very exposed

location from both the northeast and the south-southwest--the two

directions that bring the worst storm winds. At times, very large

waves can build, thanks to a significant fetch. The

anchorage at Falmouth contains 1300 moorings, but is in a very exposed

location from both the northeast and the south-southwest--the two

directions that bring the worst storm winds. At times, very large

waves can build, thanks to a significant fetch.

Similar conditions back in

May 2002 caused damage to my original anchor platform and the bow of

the boat. I worry constantly about the boat during the season,

even though the weather generally remains fairly benign.

In any event, the winds and rain

continued most of the week, and it wasn't until Thursday afternoon that

I could finally get aboard for an inspection and damage assessment. |

When I got to the boat, I discovered that the port

pendant had indeed ended up flipped on top of the anchor platform, as I

had begun to surmise from staring at it from shore.

Here is what I first saw up at the bow; the port pendant had ended up

strung between the two rollers and over the end of the platform at about

the centerline:

The pendant had of course chafed where it ran over the platform edge, as

seen here:

The platform was slightly worn under the pendant; no big deal.

What was a bigger deal, however,

became noticeable a few minutes later. First, though, I noticed that the

port chock had been pulled out of the toerail, leaving bent screws but

only minimal toerail damage. You can see the chock still hanging on in

the very first photo in the series above. This is a close-up of the

toerail beneath.

The pendant must have been pulled sharply upwards beneath the ear of the

chock to rip it out in this manner. More impressively, the heavy solid

bronze chock was actually bent in the center, pulled slightly upwards

before or while it was being ripped free.

The port pendant's outer sheating was badly chafed, but upon inspection

I observed that the main structural inner core was completely intact. I

am 100% sold on these high-strength Yale pendants. The line is still

usable as is, though of course I will replace it immediately.

On the starboard side, the line was in good condition, and

well-protected by the chafe gear that comes with the Yale lines. The

chafe gear was worn through in one area, so I turned it and replaced the

line in the chock. The slight chafe can be seen here:

OK, I've kept you waiting for the real news. Both Nathan and I were

stunned by this discovery: the 3/8" thick stainless steel plate that

provides the guts of the anchor platform was bent on the starboard side!

This first became apparent by noticing that the starboard roller was

pulled up slightly at the aft end, as seen here:

The starboard roller was also slightly deformed. Thank God the anchor

hadn't been in place during all of this.

The wooden part of the platform was cracked near the centerline, and

pulled away from the stainless plate a small amount by the bending

force:

Here, in a shot taken from the dinghy, you can see the crack clearly

between the two rollers, and also how the wooden part of the platform

has separated from the stainless on the port side (right side of the

photo):

Here is another view:

The forces that must have been at play here to bend that stainless

(which is only cantilevered out less than a foot) are mind-boggling.

Clearly, what happened is that one (or both) mooring line(s) became

caught above the platform when the bow plunged down, and then pulled

severely downward at a sharp angle as the bow rose on the next crest.

Given the way the starboard roller was deformed, I hypothesize that the

starboard pendant actually caught that, bent the roller and platform,

and then pulled free (since it was not still caught there when I saw it;

nor did it spend much time fouled there, as there was little or no chafe

to be seen).

Obviously, the port pendant remained stuck in the center, and may have

done all this damage itself, but I feel that the other side must have

been at play as well.

Otherwise, the boat was in fine shape. My brand-new pickup buoy

disappeared off the foredeck, and a few things had shuffled around in

the galley, but no big deal. The CQR anchor, which I had stored on the

sole in the head--tied to the sink pump foot pedal and wedged in place

with pillows and other gear--had not moved in the slightest.

I reinstalled the port chock with two new screws, simply moving it about

an inch for clear material, and moved the port mooring line back into

the chock. Later, I'll properly bed the chock and so forth, but I just

needed it back in place.

|

|