|

Small Projects:

Systems

This page was last updated on 26

March 2002.

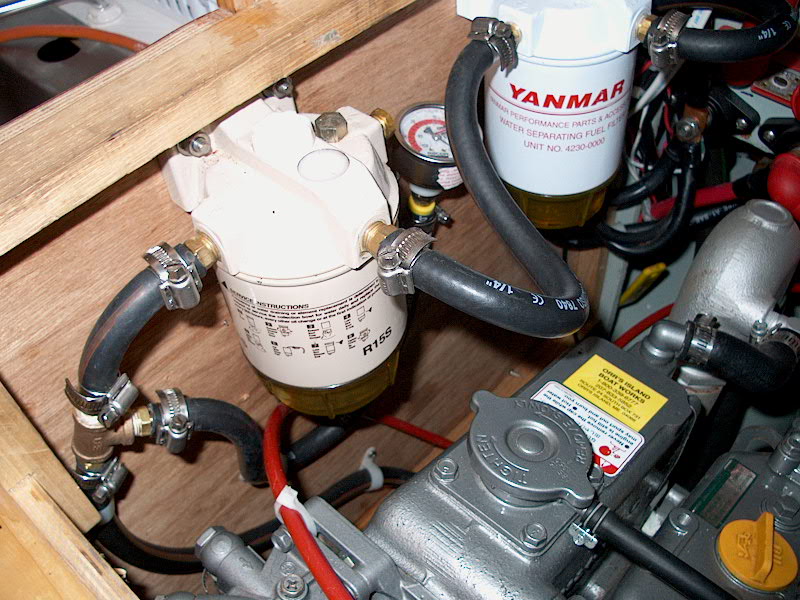

Racor Filter Vacuum

Gauge

This gauge is intended for use to assist in

determining when the fuel filters require replacement. In the most basic

terms, the gauge measures how hard the fuel pump has to suck to move fuel

through the filters. The higher the reading on the gauge, the harder the

pump is working to pull fuel through. When the gauge reaches a

predetermined level of vacuum--the literature indicates 7-10" Hg--the

filter elements require changing. I thought this would make fuel

system maintenance easier and more effective. Rather than changing filters

too often--wasting some of their filtration capacity--or, worse, leaving them

too long before cleaning, this gauge should allow me to tell in an instant what

the filters' condition is.

|

|

Installation was straightforward. On the

outlet side of my second primary fuel filter, I installed a tee in the fuel line

to the engine. Off the top of the tee, I attached a length of fuel hose

that runs to the Racor vacuum gauge. To keep it out of the way but also

easily visible for inspection, I mounted the gauge between the two primary

filters on the engine room bulkhead. The gauge is intended to be installed

in a panel somewhere, but, not having a suitable location--and not wanting Installation was straightforward. On the

outlet side of my second primary fuel filter, I installed a tee in the fuel line

to the engine. Off the top of the tee, I attached a length of fuel hose

that runs to the Racor vacuum gauge. To keep it out of the way but also

easily visible for inspection, I mounted the gauge between the two primary

filters on the engine room bulkhead. The gauge is intended to be installed

in a panel somewhere, but, not having a suitable location--and not wanting  the

gauge exposed--I elected to just leave it mounted simply in the engine

room. I secured the hose in place with a couple plastic cable clamps,

ensuring that the hose was out of the way and not chafing on anything. the

gauge exposed--I elected to just leave it mounted simply in the engine

room. I secured the hose in place with a couple plastic cable clamps,

ensuring that the hose was out of the way and not chafing on anything.

|

|

Alternator Regulator

On/Off Switch

Our large alternator charges the batteries

fast. It also uses a lot of engine power to run--a noticeable difference

with and without. Therefore, there are times when we really have no need

to use the alternator for charging while motoring; why waste the engine power

and reduce efficiency?

Because the system is set up with an external

regulator, it is easy to incorporate a switch into the circuit. The

regulator is powered through the ignition circuit; turning the key switch on

supplies power to the regulator, which then allows the alternator to charge the

batteries. If you disconnect the regulator while the engine is

running, the alternator stops charging. Sure, the alternator keeps

spinning, but is producing no power. Therefore, all I needed to do

was install a switch somewhere so that I could turn the regulator on and off at

will.

|

|

I picked up a rocker switch from the store and

installed it on my electrical board, above the LPG system controls.

Because it is difficult to cut holes out of this panel now that all the things

are wired--plus, it's such a small hole--I used a 1/4" drill bit to drill

all around the perimeter of the area I had marked out for the switch.

Then, I used a serrated utility knife to remove the rest of the material, and

fine tuned it with a file until the switch fit. The switch has a narrow

flange that does not allow much margin for error, and also relies upon a

friction fit, so I took it slowly to ensure that I didn't make the hole too

large. I was careful not to run into any of the existing wires behind the

panel while I worked. I picked up a rocker switch from the store and

installed it on my electrical board, above the LPG system controls.

Because it is difficult to cut holes out of this panel now that all the things

are wired--plus, it's such a small hole--I used a 1/4" drill bit to drill

all around the perimeter of the area I had marked out for the switch.

Then, I used a serrated utility knife to remove the rest of the material, and

fine tuned it with a file until the switch fit. The switch has a narrow

flange that does not allow much margin for error, and also relies upon a

friction fit, so I took it slowly to ensure that I didn't make the hole too

large. I was careful not to run into any of the existing wires behind the

panel while I worked.

|

|

With the switch installed, I ran a doubled piece

of #14 AWG red wire from behind the panel, along one of my existing wire chases,

and into the engine room. Once there, I connected one of the wires to the

existing power supply (which runs from the ignition switch and, originally,

directly to the regulator on/off spade); this wire now formed a continuous run

up to behind the new switch. The other wire, which will connect to the

other side of the new switch, I ran up to the regulator on/off tab and connected

it with a spade connector. With the switch installed, I ran a doubled piece

of #14 AWG red wire from behind the panel, along one of my existing wire chases,

and into the engine room. Once there, I connected one of the wires to the

existing power supply (which runs from the ignition switch and, originally,

directly to the regulator on/off spade); this wire now formed a continuous run

up to behind the new switch. The other wire, which will connect to the

other side of the new switch, I ran up to the regulator on/off tab and connected

it with a spade connector.

|

|

Then I made up the connections behind the new

switch. Without paying attention to which wire was which, I connected them

to the two screws on the back of the switch with ring terminals.

Later, when I run the engine again, I'll determine which switch position is on

and which is off, and install an indicator as necessary. Then I made up the connections behind the new

switch. Without paying attention to which wire was which, I connected them

to the two screws on the back of the switch with ring terminals.

Later, when I run the engine again, I'll determine which switch position is on

and which is off, and install an indicator as necessary.

|

|