|

Chain Locker

Bulkhead

This page was last updated on 3 March 2002

|

|

As

the initial restoration project drew to a close in the spring of 2001, certain

projects had to be postponed in the interest of getting the boat in the water

and sailing. Many of these postponed projects were things that would have

been nice from the onset, but weren't really necessary for any reason except

convenience or cosmetics. Among these projects: bookshelves, a few

minor trim pieces and--finishing off the chain locker bulkhead in the vee berth. As

the initial restoration project drew to a close in the spring of 2001, certain

projects had to be postponed in the interest of getting the boat in the water

and sailing. Many of these postponed projects were things that would have

been nice from the onset, but weren't really necessary for any reason except

convenience or cosmetics. Among these projects: bookshelves, a few

minor trim pieces and--finishing off the chain locker bulkhead in the vee berth.

From the factory, the Triton came with a

partial bulkhead separating the chain locker from the vee berth. There is

a large opening, which is great for access or ventilation, but is not

particularly attractive. I painted it bright white and we lived with it

for the first season. But I knew that once I got the boat home in the back

yard again, I would not let another season begin without building a more

attractive bulkhead here.

The new bulkhead will serve two

purposes: to be more attractive, but also to assist in stiffening the

foredeck above. Part of the structure behind the new surface will be a

laminated plywood beam spanning the width of the deck up there where you can see

that there is no structure whatsoever as the boat came from the factory. The new

beam will be behind a semi-structural--but mostly cosmetic--mahogany bulkhead

that will cover the entire area.

|

|

The

first order of business was to make a template of the shape of the overhead

(underside of the deck), and then of the entire bulkhead area. To ensure

that the new deck beam, and the mahogany bulkhead, are perfect fits, I intend to

make a full-size template of 1/4" plywood first, which I will in turn use

to cut out the actual finished pieces. This is a multi-step process,

beginning with an accurate scribed template that will be used to form the deck

beam and the top side of the new bulkhead. The

first order of business was to make a template of the shape of the overhead

(underside of the deck), and then of the entire bulkhead area. To ensure

that the new deck beam, and the mahogany bulkhead, are perfect fits, I intend to

make a full-size template of 1/4" plywood first, which I will in turn use

to cut out the actual finished pieces. This is a multi-step process,

beginning with an accurate scribed template that will be used to form the deck

beam and the top side of the new bulkhead.

To begin, I grabbed a 6"

piece of scrap pine from my shop and cut it to approximately the maximum width

of the top of the bulkhead--somewhere around 52 or 54". The wide

piece was necessary because the beam and bulkhead have to fit around a mahogany

backing block in the center (which is the backing for the big mooring bit), and

scribing it to fit will require quite a bit to be taken off the top. With

the ends cut at an angle to more than accommodate the shape of the hull, I

clamped it in place as high as it could go on the bulkhead. Unsurprisingly,

I found that the deck above was not symmetrical in the least, and the board

looked crooked when it was in fact straight and level as measured from the vee

berth platform and also the bottom of the cutout, which is parallel to the vee

berth. You can see the additional space above the board on the right side,

and also in the center where the mahogany backing block is.

|

|

Once

I was satisfied that the template was level and straight, I scribed the shape of

the deck above onto the board using a schoolhouse compass. This is a

simple matter of setting the compass to somewhat more than the widest space

above the board and then, without changing the setting, letting the point side

of the compass run along the surface to be traced, while the pencil makes a

corresponding mark on the board. I traced the entire width, and also

marked where the board hit the existing bulkhead to help reference everything

later. Once

I was satisfied that the template was level and straight, I scribed the shape of

the deck above onto the board using a schoolhouse compass. This is a

simple matter of setting the compass to somewhat more than the widest space

above the board and then, without changing the setting, letting the point side

of the compass run along the surface to be traced, while the pencil makes a

corresponding mark on the board. I traced the entire width, and also

marked where the board hit the existing bulkhead to help reference everything

later.

|

|

Cutting along this pencil line gets a close

approximation of the traced shape, but typically some fine tuning is

necessary. After my first cut, I fit the template in place and found that

there were still a few gaps on one side, so I remarked it with the scribe and

cut off the small resulting amount. When I put the template back in place, it

fit close to perfectly. Note again how uneven and out of kilter the

underside of the deck is--you can see that, although the bottom of the wooden

template is parallel with the bottom of the cutout and the surface of the vee

berth, there is much less material on the port side (left) than on the starboard

side of the template. You can also see how the mahogany backing

block in the center appears crooked as well. I also found that the

bulkhead is not square to the centerline of the boat--just like the other

bulkheads I have had to deal with on board. Cutting along this pencil line gets a close

approximation of the traced shape, but typically some fine tuning is

necessary. After my first cut, I fit the template in place and found that

there were still a few gaps on one side, so I remarked it with the scribe and

cut off the small resulting amount. When I put the template back in place, it

fit close to perfectly. Note again how uneven and out of kilter the

underside of the deck is--you can see that, although the bottom of the wooden

template is parallel with the bottom of the cutout and the surface of the vee

berth, there is much less material on the port side (left) than on the starboard

side of the template. You can also see how the mahogany backing

block in the center appears crooked as well. I also found that the

bulkhead is not square to the centerline of the boat--just like the other

bulkheads I have had to deal with on board.

|

|

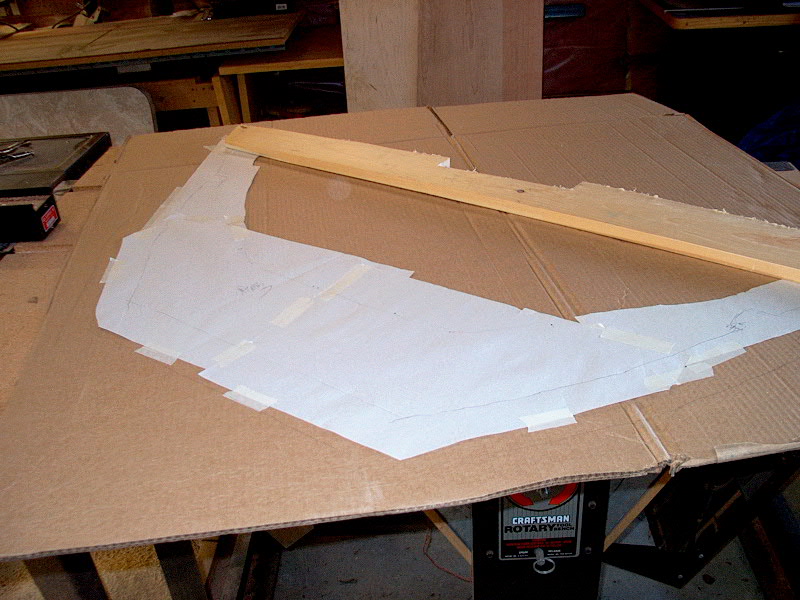

With this critical template made, I moved on

to making a template for the entire bulkhead. Temporarily removing the

pine template, I taped up some pieces of pattern paper (blank newsprint) around

the three edges (sides and bottom), leaving the pieces approximately 1-2"

away from the curved part of the hull. Then, I reclamped the board in

place across the top and made some marks to reference it to the paper portion of

the template later. Setting my dividers to 3", and using a small vise

grips to keep them locked in place (they tend to slip), I carefully traced the

curvature of the hull (and the various undulations of the fiberglass) onto the

paper pattern--and onto the wood at the top edges. I forgot to take a

picture of the  paper

template in place. While I had the paper on there, I also marked the rough

outline of the existing cutout onto the paper, so that I can easily determine

where to locate my door opening later. paper

template in place. While I had the paper on there, I also marked the rough

outline of the existing cutout onto the paper, so that I can easily determine

where to locate my door opening later.

When the tracing was complete, I removed the

wooden board and the paper template (carefully) and took them to my shop.

I had intended to create a pattern on some thin plywood, but I discovered that I

didn't have as big a sheet as I had thought. I did have some heavy

corrugated cardboard that was big enough, however. Laying the cardboard on

a flat surface. I placed the paper template on top, and carefully spread it

out. I also laid the board across the top, as this is my template for the

top portion of the bulkhead. When I was satisfied that the paper was flat

and properly aligned, I used my dividers--still set at 3"--to transfer the

line onto the cardboard. I traced the line all the way around, and then

drew a line for the top using the wooden template as my guide. It's

basically like creating your own version of a pantograph (see the photo

below). For more information on patterns, click here.

|

|

|

|

Using a sharp utility knife, I cut out the cardboard

template by following around the pencil lines. When it was all cut out, I

went back aboard the boat to fit it in place. To make it easier--and more

accurate, I had not tried to cut out the small holes where the square stiffeners

are glassed to the hull on each side of the  vee

berth. One of the advantages to cardboard is that you can easily cut and

modify it on the fly, so I figured it would be easier to create these notches on

the boat. vee

berth. One of the advantages to cardboard is that you can easily cut and

modify it on the fly, so I figured it would be easier to create these notches on

the boat.

Once I relieved the cardboard by notching it

around the stiffeners, it slipped nicely--and tightly--into place. No

further modifications were necessary. I think it all looks better

already! Before removing the template for the last time, I used a framing

square to mark a straight line parallel to and 1-1/2" above the surface of

the vee berth, and, still using the square, drew a vertical line up as

well. These will provide useful reference when the time comes to lay out

and cut the actual plywood bulkhead and the opening therein.

I

finished preparation by measuring the angle at which the hull meets the bulkhead

in a longitudinal direction. I used a bevel gauge to get this angle, which

turned out to be about 30º. This angle is important because the face side

of the new bulkhead must actually be slightly wider than the template to

compensate for the broadening of the hull. I

finished preparation by measuring the angle at which the hull meets the bulkhead

in a longitudinal direction. I used a bevel gauge to get this angle, which

turned out to be about 30º. This angle is important because the face side

of the new bulkhead must actually be slightly wider than the template to

compensate for the broadening of the hull.

After a few days' waiting, my wood order was

delivered, and I got back to work. I laid out the cardboard template on a

piece of 1/2" Honduras mahogany plywood and traced the outline.

Because the actual face of the plywood bulkhead must be wider than the

template--for the reasons described above--I laid the template out upside down

on the back side of the plywood. This means that the angled cut will be

wider on the face side than the back. I set my jigsaw blade to match the

bevel gauge at 30º and cut out the sides of the new bulkhead. I made the

top and bottom cuts with the blade set vertically, since no angle was required.

With the new bulkhead cut out, the next step

was to create the opening in the bulkhead for future access to the chain

locker. Using some marks I had placed on my original paper pattern, I laid

out the opening, taking into account the position of the existing partial

bulkhead and ensuring that the new opening was large enough to actually fit

through if I need to crawl partially in there to access anything. Before

making the cut, though, I tested the fit of the bulkhead on the boat. The

fit was pretty good, although the gaps in a couple places were a little wider

than I would have liked. I was hoping for a tight fit all around to

minimize the need for trim pieces. Unfortunately, the hull shape just

isn't necessarily consistent over the 1/2" thickness of the plywood, and

slight variations from the tight-fitting pattern occurred. In particular,

my cut on the port side to accommodate the stiffener in the hull was poorly

done, and I was upset with this. I can cover the seams with trim, but I

was really hoping for a better fit. Remember, this bulkhead serves no

structural purpose, and will not be tabbed into the hull. If I had built

it earlier in the restoration process, I probably would have tabbed it to the

hull just for good measure, and the tabbing would cover any of the small gaps

that I now have to deal with. Of course, then I would have had to find a

way to hide the ugly tabbing, so I guess I'm not really any worse off. In

any case, none of the gaps were wide enough to call for cutting a new piece of

plywood. Trim will successfully cover all later in the process. In

order to get the bulkhead pulled back away from its test position, I inserted a

couple screws into the section I plan to cut out for the opening.

|

|

Once

I was satisfied with the fit, I returned to my shop and cut out the opening with

my jigsaw. The opening is 18" wide by 13" high (I think, if

memory serves). I located it high enough so that the bottom is just

about even (a little higher) with the cutout on the existing bulkhead. I

couldn't make it much wider than I did because I didn't want to remove much of

the existing bulkhead--I'd prefer to keep the structure intact. (See the

photo at the top of the page for the existing configuration.) Once

I was satisfied with the fit, I returned to my shop and cut out the opening with

my jigsaw. The opening is 18" wide by 13" high (I think, if

memory serves). I located it high enough so that the bottom is just

about even (a little higher) with the cutout on the existing bulkhead. I

couldn't make it much wider than I did because I didn't want to remove much of

the existing bulkhead--I'd prefer to keep the structure intact. (See the

photo at the top of the page for the existing configuration.)

I also cut two Okoume 1088 plywood beams, cut

to the same template shape, for installation forward of the existing

bulkhead. Actually, one will be inserted flush with the cutout at the top,

and the other will be directly forward of that. These two pieces will be epoxied

together, to the existing bulkhead, and to the underside of the deck to help

stiffen the foredeck and also help support the top of the new cosmetic mahogany

bulkhead. Installation of these structural pieces is imminent, depending

on whether the silly abnormal high daytime temperatures continue. (40's

and even 50's in February...consistently! Wassup widdat?)

With the bulkhead all cut out and ready for

finish and installation, I moved on to building a hatch to close off the

opening. With the bulkhead still in my shop, it was the perfect

opportunity to save a number of trips back and forth to the boat for measuring

and fitting.

|

|

The first thing I had to do, however, was deal

with my rough mahogany lumber. I had ordered my mahogany dimensioned on

three sides (D3S), since I don't have a thickness planer. D3S means that

the rough 4/4 stock is planed down to its finished thickness of 3/4", and

one edge is jointed smooth. The day before my delivery was scheduled, I

received an apologetic call from the supplier with the news that they no longer

stocked finished lumber, and that unless I wanted to pay a steep price for

planing, I would receive the mahogany in the rough state. (The cherry I

ordered came properly planed D3S.) I elected to go ahead with the rough

stuff and deal with smoothing it afterwards. The first thing I had to do, however, was deal

with my rough mahogany lumber. I had ordered my mahogany dimensioned on

three sides (D3S), since I don't have a thickness planer. D3S means that

the rough 4/4 stock is planed down to its finished thickness of 3/4", and

one edge is jointed smooth. The day before my delivery was scheduled, I

received an apologetic call from the supplier with the news that they no longer

stocked finished lumber, and that unless I wanted to pay a steep price for

planing, I would receive the mahogany in the rough state. (The cherry I

ordered came properly planed D3S.) I elected to go ahead with the rough

stuff and deal with smoothing it afterwards.

I do own a jointer, although I hadn't used it

for years. The jointer has always been the most frustrating tool in my

shop. I find setting it properly so that it makes the right cut is nearly

impossible; this problem is probably compounded by the fact that it's an

inexpensive model, which are notoriously difficult to set up. Add in the

long periods of neglect between use attempts, and success seems impossible.

However, I thought I would give it a

try. It has a six-inch blade, so it was wide enough to deal with the

pieces I had to smooth. I spent some time cleaning it up, and setting it

up in what appeared to be the proper way. However, as I began running the

boards through, it was obvious that the setup was off. I was getting

tapered cuts--thicker at one end and virtually nothing at the other. I

tried fine tuning the tables for a while, but soon got sick of it and gave up

yet again. Anyone want a cheap jointer?

I decided to simply use my table saw to resaw

the boards and cut them to the proper thickness of 3/4". Fortunately,

the rough edges of the boards were straight enough that I could use one as a

guide to rip a small amount off the opposite edge. Then, by turning the

board around, I placed the now-smooth edge against the saw fence and trimmed the

rough board to a little wider than the desired width. Because the board I

was using featured some bends in it, I cut off a piece a little longer than I

needed before continuing. The shorter piece was flat over its length,

making further cuts more accurate. Raising the blade on the saw as high as

it would go, and setting the fence to just about an inch away from the blade, I

carefully ran the board through on edge. The saw blade made a pretty

smooth cut as I pushed the board through, although the full height of the blade

wasn't quite enough to get through the whole board. I had to turn the

board around and make another pass to complete the cut.

With one side resawn, I turned the board

around, set the fence to a hair over 3/4", and repeated the process on the

other face. I ended up with a fairly smooth board of the proper thickness;

the table saw cut is a whole lot smoother than the rough cut was, and should be

easy to sand smooth later in the process. If this were oak instead of

mahogany, this entire process would have been substantially more difficult, if

not infeasible. Fortunately, mahogany mills beautifully. I only did

this to enough stock for the jobs immediately at hand--but I still have 3

unfinished boards that are about 8" wide by 8 feet long that I'll have to

deal with. Maybe I'll take them to a local shop for planing. The

whole process I described took quite a bit of time.

With the stock prepared to rough dimensions, I

moved on to milling the rails and stiles for my hatch into the chain

locker. As with the other doors on the interior, I milled the pieces to

1-1/2" width, and sized their lengths to accommodate a standard 3/8"

overlay on the cabinet. I decided on a single door--I'm not yet sure if

I'm going to hinge it on the bottom or on one side. Originally, I had

planned on two doors meeting in the middle. However, I realized that I had

not milled enough of the mahogany down to the proper thickness (as described

above), since I had only taken the dimensions of the rough opening into account,

and failed to account for the extra rails in the middle that would be required

for a pair of doors. I didn't want to repeat the dimensioning process, so

I decided upon one door. The opening is only 18" x 13" anyway,

so it's not as if the single door will be way too big.

|

|

With

the four pieces for the door frame cut, I mixed up a small batch of thickened

epoxy. Because of the strength of the epoxy, I am relying only on butt

joints for the corners--no fancy joinery. In other instances I find it

desirable to create a stronger joint at the corners, but haven't found it

necessary on the doors for the boat--the epoxy is simply strong enough that the

butt joints seem to work well. They certainly take less time to

create. I glued up the door frame and clamped it securely to sit overnight

before continuing. With

the four pieces for the door frame cut, I mixed up a small batch of thickened

epoxy. Because of the strength of the epoxy, I am relying only on butt

joints for the corners--no fancy joinery. In other instances I find it

desirable to create a stronger joint at the corners, but haven't found it

necessary on the doors for the boat--the epoxy is simply strong enough that the

butt joints seem to work well. They certainly take less time to

create. I glued up the door frame and clamped it securely to sit overnight

before continuing.

With that out of the way, I decided to go

ahead with installing the new deck beams at the chain locker. The weather

was warm enough to support epoxy. Before going ahead, I took the two

plywood pieces up to the boat and checked the fit. There were a few gaps,

but nothing serious. Really, this beam's structural purpose is extremely

limited. I see no reason to make this thing bulletproof. The boat

does not need the structure; it's really there to just minimize some of the flex

that naturally occurs in the wide foredeck. Therefore, I won't be spending

hours and hours honing the fit to perfection, and glassing it in place with

multiple layers of cloth. This seems completely unnecessary to me for this

application. Plus, with the finished surfaces of the vee berth (including

the fabric liner), creating proper tabbing is not possible without destroying

the fabric. In hindsight, I suppose I should have installed this beam at

an early stage of the project. But, considering that it is really

unnecessary from any structural standpoint, I think just epoxying it in place

with a thick mixture will be more than sufficient and will add that additional

support to the foredeck.

|

|

Once

I was satisfied with the fit of the two pieces--one goes just forward of the

existing bulkhead, the other fits flush in between the cutout at the top--I

mixed up a pretty large batch of very thick epoxy, using 406 colloidal

silica. Then, up at the boat, I applied the mixture to the top edge of the

forwardmost plywood beam, and clamped it up in place. pressing the beam into the

thick band of epoxy. I then coated the facing side of the beam with more

epoxy, layered more on top of the second beam, and clamped that one in place as

well. To help secure the two beams, I drove some stainless steel screws as

necessary to augment the clamps. The screws will stay in place in the

completed installation. I cleaned up the excess epoxy and filled any small

gaps with the remaining mixture. I left the beams clamped for a couple

days. Again: remember that even though the beam looks

crooked in the photo, the bottom edge is level and parallel with the vee berth

and bulkhead cutout. It's just the foredeck above that is out of

whack. I think it was molded this way originally. Once

I was satisfied with the fit of the two pieces--one goes just forward of the

existing bulkhead, the other fits flush in between the cutout at the top--I

mixed up a pretty large batch of very thick epoxy, using 406 colloidal

silica. Then, up at the boat, I applied the mixture to the top edge of the

forwardmost plywood beam, and clamped it up in place. pressing the beam into the

thick band of epoxy. I then coated the facing side of the beam with more

epoxy, layered more on top of the second beam, and clamped that one in place as

well. To help secure the two beams, I drove some stainless steel screws as

necessary to augment the clamps. The screws will stay in place in the

completed installation. I cleaned up the excess epoxy and filled any small

gaps with the remaining mixture. I left the beams clamped for a couple

days. Again: remember that even though the beam looks

crooked in the photo, the bottom edge is level and parallel with the vee berth

and bulkhead cutout. It's just the foredeck above that is out of

whack. I think it was molded this way originally.

|

|

Please click here to

continue the project. |

|