|

Propane Stove &

Fuel System

This page was last updated on 24

March 2002.

Stove and Basic

Installation Gas

Control Panel Installation

LPG Tank,

Regulator, and Solenoid Installation

LPG Vapor Sniffer and Alarm System Installation

|

With the cabinetry around the stove and galley

done, and the stove (which had been stored in the head since August) generally

in the way, I decided to turn to the installation in its proper place.

Previously, I built a cabinet for the stove--more of an alcove, really, with

dimensions based on the size required for the unit. The stove is a Seaward

Hillerange 2-burner with oven. With the cabinetry around the stove and galley

done, and the stove (which had been stored in the head since August) generally

in the way, I decided to turn to the installation in its proper place.

Previously, I built a cabinet for the stove--more of an alcove, really, with

dimensions based on the size required for the unit. The stove is a Seaward

Hillerange 2-burner with oven. |

|

To install the gimbaled stove, I first cut a

paper pattern of the side of the stove, with the gimbal point clearly parked,

and test fit it on the side of the alcove, swinging it to and fro to see how far

it would go without hitting any obstructions. I moved it around until I

felt I had found the proper place, and marked the gimbal center. I transferred

the measurement to the other side in preparation for installing the gimbal

brackets. I bolted these brackets to the cabinets with #10 machine screws;

I had to use bolts since screws would have penetrated the 1/2" plywood

enclosure. Then, it was a matter of lifting the stove into the brackets,

which are equipped with clips that prevent the stove from jumping up out of the

brackets. To install the gimbaled stove, I first cut a

paper pattern of the side of the stove, with the gimbal point clearly parked,

and test fit it on the side of the alcove, swinging it to and fro to see how far

it would go without hitting any obstructions. I moved it around until I

felt I had found the proper place, and marked the gimbal center. I transferred

the measurement to the other side in preparation for installing the gimbal

brackets. I bolted these brackets to the cabinets with #10 machine screws;

I had to use bolts since screws would have penetrated the 1/2" plywood

enclosure. Then, it was a matter of lifting the stove into the brackets,

which are equipped with clips that prevent the stove from jumping up out of the

brackets.

Next, I drilled a hole in the cabinet opposite

the gimbal lock lever and installed the supplied cover plate. This

completed the physical installation of the stove unit itself.

|

|

At

this stage, I also installed a Trident solenoid control panel in the

electrical panel across from the stove. This panel features its own

circuit breaker and indicator light. At the time I purchased the panel,

the s tore did not have one with integral alarm in stock, so I bought the

regular panel. It can be upgraded to include a sniffer, alarm, and auto

shutoff, which I will do a little later. At

this stage, I also installed a Trident solenoid control panel in the

electrical panel across from the stove. This panel features its own

circuit breaker and indicator light. At the time I purchased the panel,

the s tore did not have one with integral alarm in stock, so I bought the

regular panel. It can be upgraded to include a sniffer, alarm, and auto

shutoff, which I will do a little later.

Installing the Trident panel was

a matter of cutting an appropriate hole in my wooden panel, and screwing the

panel into place. Then, I ran a pair of wires (red and yellow) from the

back of the panel, behind the engine, and along the starboard side of the hull,

following my existing wiring runs, and dead-ending the wires in the head, where

I would eventually create a final run up to the propane solenoid, when

installed. However, at this point (February 2001), I had bigger fish

to fry, so to speak, as I rushed to get the boat ready for launch.

Completing the LPG installation would have to wait until later.

Update--July

2001

Well, it took nearly two months after

launching the boat to finally get the propane tank and hoses installed!

Working with the engine and other projects--plus enjoying the boat and

sailing--meant that my timeframe got delayed somewhat. Plus, the fact that

I didn't have a clear idea how I was going to install the tank meant that I

tended to procrastinate on starting the job.

My initial thought, way back when, had been to

install a dedicated locker in the lazarette. However, after cutting the

hole and sizing things up, it seemed to be a complicated proposal--and it would

eat up all the valuable storage space in the lazarette. After having the

boat in the water for awhile, it was obvious that I didn't want to give up this

space.

The next thought was to build a deck box to

hold the tank and secure it somewhere on the deck, perhaps by the mast or on the

foredeck. This simplifies matters because, with the tank essentially open

to the atmosphere abovedecks, many of the critical safety considerations are

eliminated, since the gas, if it were to leak, would just blow overboard rather

than collect somewhere in the bilges, as it would with a belowdecks tank.

I went forward with this plan, and built a nice mahogany box for the tank (a

horizontal 10-lb. aluminum tank). I varnished it up nicely, and finally

was ready to try it on the boat.

|

|

An

ideal place for this box would have been behind the mast, immediately forward of

the bump in the cabin trunk. Unfortunately, on my boat I installed a solid

boom vang that cuts into this space; I was certainly not going to give up the

vang for the sake of propane storage. I had thought that maybe the box

would fit to either side of the mast, but this didn't work either. The

foredeck, just forward of the cabin trunk, had potential, but it definitely took

up more room than ideally desired, and I worried a little about genoa sheets

catching on the box. An

ideal place for this box would have been behind the mast, immediately forward of

the bump in the cabin trunk. Unfortunately, on my boat I installed a solid

boom vang that cuts into this space; I was certainly not going to give up the

vang for the sake of propane storage. I had thought that maybe the box

would fit to either side of the mast, but this didn't work either. The

foredeck, just forward of the cabin trunk, had potential, but it definitely took

up more room than ideally desired, and I worried a little about genoa sheets

catching on the box.

|

|

Holding this idea in reserve, I looked into

other options. After much discussion, eventually we decided to install the

tank--without a box--on the coachroof aft of the mast. While the tank and

regulator will be exposed here, it seemed the best all-round location.

We'll build a canvas cover for the whole thing to clean it up a little and help

protect it from the weather and other damage. I don't know what I'm going

to do with my nice deck box.

To

make the tank easily removable for filling, I installed four bolts from inside

the cabin (in the head); these are long enough to penetrate the cabin, allow for

room for a nut and washer (to hold the bolts permanently in place), and allow

for the tank to sit over the exposed ends for securing with wing nuts for easy

removal. I gobbed lots of caulk around the boltholes and beneath the

fender washers. To

make the tank easily removable for filling, I installed four bolts from inside

the cabin (in the head); these are long enough to penetrate the cabin, allow for

room for a nut and washer (to hold the bolts permanently in place), and allow

for the tank to sit over the exposed ends for securing with wing nuts for easy

removal. I gobbed lots of caulk around the boltholes and beneath the

fender washers.

|

|

The

tank rests neatly on these four bolts, and is secured with wing nuts and lock

washers. It's open to the atmosphere, so venting won't be a concern.

It clears the boom vang nicely, and is pretty much out of the way here. The

tank rests neatly on these four bolts, and is secured with wing nuts and lock

washers. It's open to the atmosphere, so venting won't be a concern.

It clears the boom vang nicely, and is pretty much out of the way here.

|

|

I

installed a remote regulator assembly, attached to the tank with a pigtail, on

the forward end of the cabin trunk bump. It's sort of tucked in behind the

"top" end of the tank, the end with the valve assembly, which helps

protect it from the weather. To the regulator, I attached, using a series

of brass nipples, an electric solenoid control, which is switched on and off by

a panel in the cabin. This valve keeps the system closed off when not in I

installed a remote regulator assembly, attached to the tank with a pigtail, on

the forward end of the cabin trunk bump. It's sort of tucked in behind the

"top" end of the tank, the end with the valve assembly, which helps

protect it from the weather. To the regulator, I attached, using a series

of brass nipples, an electric solenoid control, which is switched on and off by

a panel in the cabin. This valve keeps the system closed off when not in  use;

I will soon be installing a vapor alarm for the bilge, which, in addition to an

audible alarm, will shut the use;

I will soon be installing a vapor alarm for the bilge, which, in addition to an

audible alarm, will shut the    solenoid if vapors are detected. Downstream

of the solenoid, the 15' hose run is secured, which runs through a vapor-tight

cable fitting into the head, then across the bulkhead, where it disappears

behind the main cabin settee backs for its run aft to the stove. I

installed a plastic cover over the regulator to protect it and the integral vent

from water. The solenoid wires run through another vapor-tight fitting near the

hose exit, and are tied up alongside. I need to build a wooden trim piece

to hide the hose and wiring inside the boat--this will probably happen during

the off season. (I copped out--see my trim solution here.) solenoid if vapors are detected. Downstream

of the solenoid, the 15' hose run is secured, which runs through a vapor-tight

cable fitting into the head, then across the bulkhead, where it disappears

behind the main cabin settee backs for its run aft to the stove. I

installed a plastic cover over the regulator to protect it and the integral vent

from water. The solenoid wires run through another vapor-tight fitting near the

hose exit, and are tied up alongside. I need to build a wooden trim piece

to hide the hose and wiring inside the boat--this will probably happen during

the off season. (I copped out--see my trim solution here.)

|

|

Finally,

I completed the wiring connections at the tank (solenoid) end and behind the

Trident panel according to the instructions included with the panel. Finally,

I completed the wiring connections at the tank (solenoid) end and behind the

Trident panel according to the instructions included with the panel.

|

|

The regulator assembly is admittedly not the

most attractive thing in the world, but, with the tank installed, is fairly

hidden--we plan a canvas cover for everything soon anyway. Sometimes,

function has to come before form (not often, though...). The regulator assembly is admittedly not the

most attractive thing in the world, but, with the tank installed, is fairly

hidden--we plan a canvas cover for everything soon anyway. Sometimes,

function has to come before form (not often, though...).

Before starting the system for the first time,

I performed several leak tests. First, I opened the tank valve until the

pressure gauge on the regulator rose to 110 (a normal reading for 70

degrees). Then, I shut the valve and waited a number of minutes before

checking the gauge again. It didn't move; if there had been a leak

somewhere in the line, or at a fitting, the pressure would have gone down.

Then, I brushed some very soapy water on every joint and nipple, looking for

bubbles that would indicate leakage. None. With these critical

safety tests complete, I was able to test-light the stove; in its initial test,

the stove and oven worked great! We used it for an entire--if

brief--season with excellent results. I didn't get around to installing

the vapor-detector kit right away.

Update 19

March 2002

Finally, I got around to

installing the sniffer/alarm system after the first season. It was one of

those small projects that I just could never find the time for during the

summer.

Installation was fairly

straightforward. The kit includes a sensor assembly, which is to be

mounted somewhere fumes might collect if there were a leak, and an additional

circuit board and reset button that is intended for installation on the original

Trident gas control panel. These panels are sold complete with the alarm

setup already installed, or separately--as I had purchased them. I did

this because the store didn't have the complete system in stock when I needed

it, so I bought the normal panel at that time, and ordered the upgrade alarm kit

later on.

|

|

This

is the new circuit board. It features whatever electronic wizardry that

makes it work, along with four new wires, and an alarm light circuit (left, with

the yellow wires) and a reset button--the black knob next to the bundle of four

wires. I followed the included instructions and installed it on the back

of the Trident panel. First, I had to enlarge the cutout in my

switch panel board to allow it to fit properly. Access is tight, so

I used a serrated narrow-blade knife that I had on board to saw out the

opening. It worked surprisingly well, but I didn't get a perfect cut--not

that it matters, since the opening is hidden anyway. This

is the new circuit board. It features whatever electronic wizardry that

makes it work, along with four new wires, and an alarm light circuit (left, with

the yellow wires) and a reset button--the black knob next to the bundle of four

wires. I followed the included instructions and installed it on the back

of the Trident panel. First, I had to enlarge the cutout in my

switch panel board to allow it to fit properly. Access is tight, so

I used a serrated narrow-blade knife that I had on board to saw out the

opening. It worked surprisingly well, but I didn't get a perfect cut--not

that it matters, since the opening is hidden anyway.

|

|

Then, I removed two

blanks that filled the holes for the new reset button and red alarm light, and

installed the circuit board over two studs that I screwed into threaded holes

provided in the back of the panel. The studs hold the circuit board in the

proper place. I installed a red plastic lens for the alarm light, and

pressed the wired bulb into the lens from the back. Then, I attached two

of the included wires to the original circuit breaker switch, as directed by the

instructions. The other two wires will be connected a little later on,

after I install the vapor sensor. Then, I removed two

blanks that filled the holes for the new reset button and red alarm light, and

installed the circuit board over two studs that I screwed into threaded holes

provided in the back of the panel. The studs hold the circuit board in the

proper place. I installed a red plastic lens for the alarm light, and

pressed the wired bulb into the lens from the back. Then, I attached two

of the included wires to the original circuit breaker switch, as directed by the

instructions. The other two wires will be connected a little later on,

after I install the vapor sensor.

|

|

I

installed the vapor sensor in a compartment beneath the stove. I was a

little unsure where to put this. My first instinct was the bilge, but

looking at the sensor I decided that it looked entirely UN-waterproof, and the

chances of it getting at least damp are pretty high were it to be located in the

bilge. I settled for the space directly beneath the stove, where the water

pumps are installed. It seems logical that propane might collect here if

there were a leak around the stove. I attached it with a blob of

caulk, and duct-taped it in place while the caulk cured. I

installed the vapor sensor in a compartment beneath the stove. I was a

little unsure where to put this. My first instinct was the bilge, but

looking at the sensor I decided that it looked entirely UN-waterproof, and the

chances of it getting at least damp are pretty high were it to be located in the

bilge. I settled for the space directly beneath the stove, where the water

pumps are installed. It seems logical that propane might collect here if

there were a leak around the stove. I attached it with a blob of

caulk, and duct-taped it in place while the caulk cured.

|

|

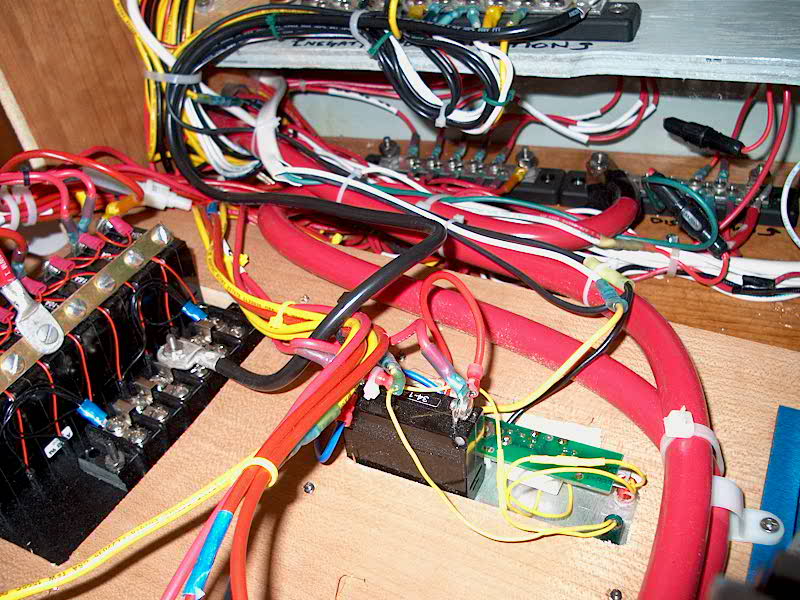

The

sensor is connected to a power source and to other wires on the Trident control

panel with a length of triplex wire. I ran the wire behind the engine room

and through my wire chases to the electrical panel, and connected the various

wires as directed by the instructions. One wire runs to the positive

distribution buss; another, along with one of the wires on the new circuit

board, grounds to the negative distribution buss; and the third connects to the

final wire on the circuit board (exact function unknown...but that's where it

goes!). You can see these wires secured to one of the thick red

battery cables in the photo towards the right center. The negative buss is

at the top of the photo; the positive buss is just below, with the red wires

attached. The

sensor is connected to a power source and to other wires on the Trident control

panel with a length of triplex wire. I ran the wire behind the engine room

and through my wire chases to the electrical panel, and connected the various

wires as directed by the instructions. One wire runs to the positive

distribution buss; another, along with one of the wires on the new circuit

board, grounds to the negative distribution buss; and the third connects to the

final wire on the circuit board (exact function unknown...but that's where it

goes!). You can see these wires secured to one of the thick red

battery cables in the photo towards the right center. The negative buss is

at the top of the photo; the positive buss is just below, with the red wires

attached.

|

UPDATE

The alarm

system worked fine when first connected, but at one point during our cruise it

started going off intermittently, then almost continuously, so eventually I had

to disconnect the buzzer. Troubleshooting and repair of this is on the

project list for winter 2002. As usual, these silly electronic devices are

more trouble than they're worth. In 2008, I removed the sniffer and its

wiring completely. |

|