|

Stepping

the Mast: The First Time

This page was last updated on 29 November 2001

|

|

After the boat was launched, we towed her over

next door to the yacht club, where I spent some time rigging up the spreaders

and jumpers. With this done, we moved on to the boatyard next door and

tied up in the Travellift slip, where their boom truck was located. We

pretty much stepped back and let the riggers deal with things from that

point--hooking up the crane cable and

bridle, then lifting the mast to a vertical position, lowering it into the step,

and attaching the stays. I was a little nervous about the whole process,

since all the rigging was new and I wasn't sure it would all fit properly.

However, everything came off without a hitch, although the backstay barely made

it--with the headstay turnbuckle all the way open, and the backstay the same, we

got the clevis pin through, and tightened it enough to pin the

turnbuckles. Phew! Especially gratifying was that my headstay, which

I had measured, cut and installed the roller furler, fit properly with no

hitches. |

|

|

When we got over to the yard, the

first thing they did was raise the mast up off the boat using their boom

truck. |

|

|

The mast nearly vertical. I had

the spreaders and everything all rigged beforehand, being careful to

pull the spreader ends up as high as possible before securing the monel

mousing and spreader boots. As the shrouds are tensioned later,

this tends to pull the spreader tips slightly downward, so it's good to

start out with them as high as possible. |

|

|

Lowering the mast down onto the

step. I'm holding the headstay to keep it from dragging around on

the deck and scratching the paint. The uppers and lowers are about

to be attached. |

|

|

Here we're struggling to get the

backstay attached to the chainplate. The headstay is already

attached and its turnbuckle opened all the way--the new rigging will

stretch, so this should be easier in the future. We did get the

backstay attached, obviously. |

|

|

The mast is successfully

stepped! |

|

|

With

the mast up, we moved back over to the yacht club for the rest of the

afternoon. The boat looked great with the stick up--much better than

without. With

the mast up, we moved back over to the yacht club for the rest of the

afternoon. The boat looked great with the stick up--much better than

without.

|

|

With the mast up, I made it all official by

installing the new ensign in the flagpole socket on the taffrail. With the mast up, I made it all official by

installing the new ensign in the flagpole socket on the taffrail.

|

|

Mast

Wiring Connections

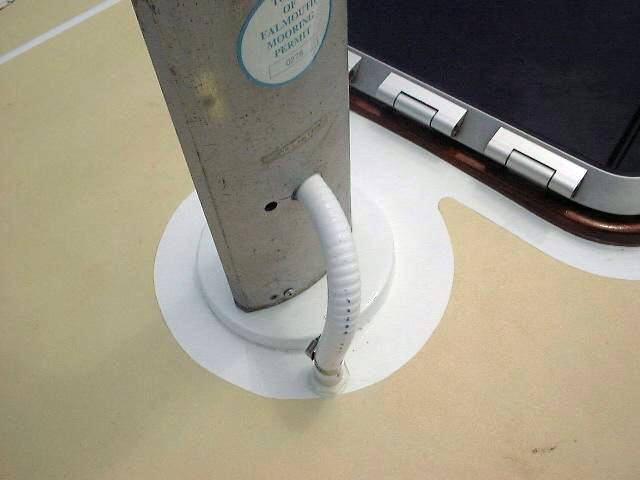

I had heard about a great idea for dealing with the mast wires

and the through-deck situation. It involved a through hull fitting

installed in the deck, to which was attached a hose that ran up into the mast

above deck level; the wires run through the hose, through the through hull

fitting, and into the boat. It sounded great, and I decided to copy the

idea.

I

installed a plastic (acetic) 3/4" through hull fitting in the deck just aft

of the mast beam, and sealed it well with polysulfide. With the mast still on

the ground, I drilled a 1" hole about 10" above the base, through

which the wires run. With the mast stepped, I cut a length of nice white

sanitation hose to the proper length, ran the wires through, and secured the

hose to the through hull with a hose clamp, inserted the other end into

the mast hole, and sealed around it with silicone caulk. A very neat

installation, and it should be perfectly watertight. It is also easy

enough to dismantle every year when the mast comes out. I

installed a plastic (acetic) 3/4" through hull fitting in the deck just aft

of the mast beam, and sealed it well with polysulfide. With the mast still on

the ground, I drilled a 1" hole about 10" above the base, through

which the wires run. With the mast stepped, I cut a length of nice white

sanitation hose to the proper length, ran the wires through, and secured the

hose to the through hull with a hose clamp, inserted the other end into

the mast hole, and sealed around it with silicone caulk. A very neat

installation, and it should be perfectly watertight. It is also easy

enough to dismantle every year when the mast comes out.

|

|

Inside the boat, I cut the wires to length and attached them

to a terminal block that I screwed to the mast beam. Then, I attached the

wires I had run inside the boat earlier during the wiring to the other sides of

the appropriate terminals, completing the circuits. I connected the VHF

antenna using two PL-259 connectors and a splice fitting in between, allowing

for easy connection and disconnection in the future. Inside the boat, I cut the wires to length and attached them

to a terminal block that I screwed to the mast beam. Then, I attached the

wires I had run inside the boat earlier during the wiring to the other sides of

the appropriate terminals, completing the circuits. I connected the VHF

antenna using two PL-259 connectors and a splice fitting in between, allowing

for easy connection and disconnection in the future.

Soon, I'll construct some wooden trim to cover the wires and

terminal block. Details coming soon.

10/1/01: OK, details aren't coming soon--the

season has come and gone, and I never got around to this project. It's on

the list for the winter! I'll post details as soon as the project is

underway. (See Small Projects)

|

|