|

Constructing a New Galley

This page was last updated on 30 January 2002

Layout

and construction of a new, super-insulated icebox | Layout

and construction of the engine box and companionway ladder

Layout

and construction of the galley countertop, stove enclosure, and storage

| Rebuilding

the Other Parts of the Interior

Installing

the Stove and LPG System | Galley

Water Systems

|

|

Please note that each section of this page details a single

portion of the galley construction from start to finish, or nearly so.

Therefore, while each individual section may be chronological in terms of that

part of the project, in most cases several of the projects were underway at the

same time, and were more or less at a consistent level of completion with one

another. |

|

Engine

Box and Companionway

I began rebuilding the galley and

interior with the enclosure around the

engine, so that I can finally get some proper steps down into the cabin and

get rid of the milk crate I have been using for the past few months.

Plus, building around the engine to give it the necessary space is one of the

most important considerations in the new interior design.

The first thing to do was to cut out the

settee on the port side where the icebox will eventually reside, to make it as

big as possible, and to allow for the 4" of insulation I will be

installing. See details here.

I did this first so that I would have the best access to make the cut.

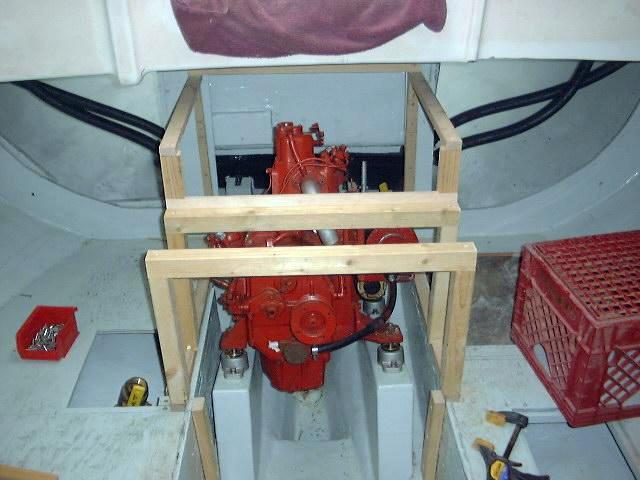

Next,

I constructed a framework around the engine, incorporating two different

levels, the lower of which will be the same height as the adjacent galley

countertop (30" from the cabin sole). These staggered platforms are

necessary to take into account the physical dimensions of the engine,

but also work out well for steps. The two athwartships cross braces,

designed to support the weight of the step, are easily removable for wide open

engine access by removing four screws from the top. I used a combination

of oak, cypress, and fir that I had in my scrap collection, all secured with

#8 x 1 1/2" stainless steel screws. Next,

I constructed a framework around the engine, incorporating two different

levels, the lower of which will be the same height as the adjacent galley

countertop (30" from the cabin sole). These staggered platforms are

necessary to take into account the physical dimensions of the engine,

but also work out well for steps. The two athwartships cross braces,

designed to support the weight of the step, are easily removable for wide open

engine access by removing four screws from the top. I used a combination

of oak, cypress, and fir that I had in my scrap collection, all secured with

#8 x 1 1/2" stainless steel screws.

|

|

The

next step was to cut and install plywood as necessary to cover the sides of

the engine box, as well as the steps and front. To do this, I made

patterns (click here for a brief lesson in pattern

making), transferred the lines to the plywood, and cut the pieces out. I

used 9mm merranti marine plywood, a high quality, void-free, 7-ply product,

for the areas that will be hidden or covered with Formica, and 1/2"

cherry plywood for the vertical step riser and the large panel at the front of

the engine box. The various panels are designed for easy removal to gain

quick and simple access to the engine for inspection or service.

Eventually, the edges of the panels will be hidden behind solid cherry trim

pieces, which will also act as channels into which the panels can slide.

All the pieces are loosely installed at the moment, but as the adjacent

cabinetry is installed things will fall into place. The

next step was to cut and install plywood as necessary to cover the sides of

the engine box, as well as the steps and front. To do this, I made

patterns (click here for a brief lesson in pattern

making), transferred the lines to the plywood, and cut the pieces out. I

used 9mm merranti marine plywood, a high quality, void-free, 7-ply product,

for the areas that will be hidden or covered with Formica, and 1/2"

cherry plywood for the vertical step riser and the large panel at the front of

the engine box. The various panels are designed for easy removal to gain

quick and simple access to the engine for inspection or service.

Eventually, the edges of the panels will be hidden behind solid cherry trim

pieces, which will also act as channels into which the panels can slide.

All the pieces are loosely installed at the moment, but as the adjacent

cabinetry is installed things will fall into place.

|

|

With

the basic pieces of the engine box and steps in place, and after completing some of the adjacent cabinetry (see other sections of this page for

descriptions), I installed satin white Formica on the horizontal surfaces.

To protect the surfaces during the remainder of construction, I laid cardboard

over the vulnerable areas. With

the basic pieces of the engine box and steps in place, and after completing some of the adjacent cabinetry (see other sections of this page for

descriptions), I installed satin white Formica on the horizontal surfaces.

To protect the surfaces during the remainder of construction, I laid cardboard

over the vulnerable areas.

With only the two steps

built into the top

portion of the engine box, I spent several months climbing in and out of the

boat by stepping down on to the port settee--acceptable during construction,

but of course not good enough for the long haul.  Some

sort of steps at the lower engine box were needed. Last summer, I saw a nice,

simple set of removable steps on a Hinckley Pilot (seen in the thumbnail to

the right), and thought a similar setup would work well on Glissando.

Basically, the steps are a self-contained unit, secured with simple latches,

that can be easily removed to gain access to the engine or if more space is

required in the galley. I designed the steps to be narrow enough to

allow galley access in the narrow Triton cabin, and also to allow the oven

door to be opened when they are in place. A normal, centerline ladder

would have been continually in the way. The new step unit will be

installed on the port side, nestled against the settee, leaving a foot or so

of open space in front of the stove and galley. Some

sort of steps at the lower engine box were needed. Last summer, I saw a nice,

simple set of removable steps on a Hinckley Pilot (seen in the thumbnail to

the right), and thought a similar setup would work well on Glissando.

Basically, the steps are a self-contained unit, secured with simple latches,

that can be easily removed to gain access to the engine or if more space is

required in the galley. I designed the steps to be narrow enough to

allow galley access in the narrow Triton cabin, and also to allow the oven

door to be opened when they are in place. A normal, centerline ladder

would have been continually in the way. The new step unit will be

installed on the port side, nestled against the settee, leaving a foot or so

of open space in front of the stove and galley.

|

|

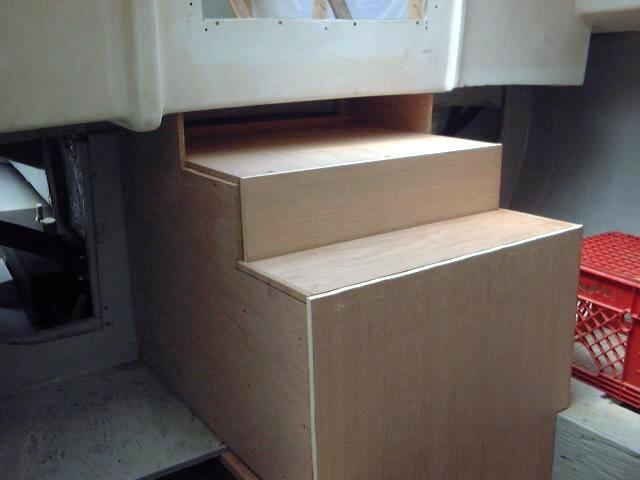

To

build the removable steps, I

determined the size necessary--there are three steps, with an 8" rise,

and the treads are 8" wide--and cut the various pieces to size.

Each succeeding step is 3" deeper than the one above. I made the

unit from 1/2" cherry plywood with solid cherry trim. The treads

are two layers of 1/2" plywood glued together and screwed to cleats

attached to the insides of the plywood sides. I plan to install the

steps with draw latches for a tight, secure fit, but they'll be easily

removable when necessary. The steps will be finished to match the

surrounding woodwork. One side of the frame is shorter than the other to

accommodate the curvature of the hull where the steps will be mounted. To

build the removable steps, I

determined the size necessary--there are three steps, with an 8" rise,

and the treads are 8" wide--and cut the various pieces to size.

Each succeeding step is 3" deeper than the one above. I made the

unit from 1/2" cherry plywood with solid cherry trim. The treads

are two layers of 1/2" plywood glued together and screwed to cleats

attached to the insides of the plywood sides. I plan to install the

steps with draw latches for a tight, secure fit, but they'll be easily

removable when necessary. The steps will be finished to match the

surrounding woodwork. One side of the frame is shorter than the other to

accommodate the curvature of the hull where the steps will be mounted.

|

|

For

easy removal, as well as a tight, secure fit in place, I installed the steps

with draw clamps. When latched, these draw the two pieces together for a

tight fit. I used two of these on the steps, and they work pretty well,

but, because of the curvature of the hull and the short leg's tendency to want

to slip down the angle, some further restraint is needed. To prevent

movement and help lock the steps into place, I installed a wooden cleat on the

angled portion of the hull. The side of the step fits between this cleat

and the side of the settee, effectively preventing it from its tendency to

slide down. To allow for the

new cabin sole that will be installed in a couple months, I placed a scrap of

plywood the same thickness as the new sole beneath the steps before installing

the hardware. I also had to cut away a small portion of the settee

fiddle on the port side aft, so that the steps could fit tightly against the

settee. For

easy removal, as well as a tight, secure fit in place, I installed the steps

with draw clamps. When latched, these draw the two pieces together for a

tight fit. I used two of these on the steps, and they work pretty well,

but, because of the curvature of the hull and the short leg's tendency to want

to slip down the angle, some further restraint is needed. To prevent

movement and help lock the steps into place, I installed a wooden cleat on the

angled portion of the hull. The side of the step fits between this cleat

and the side of the settee, effectively preventing it from its tendency to

slide down. To allow for the

new cabin sole that will be installed in a couple months, I placed a scrap of

plywood the same thickness as the new sole beneath the steps before installing

the hardware. I also had to cut away a small portion of the settee

fiddle on the port side aft, so that the steps could fit tightly against the

settee.

|

|

To

protect the top two countertop surfaces, I installed two cherry step pads for the

upper steps. The pads are about 5" by 4", and feature a

grooved top surface for traction. These will prevent all the footfalls

from landing directly on our sandwiches or on the steps, which are going to end up being a useful

part of the galley countertop. I installed the pads with screws from

beneath. To

protect the top two countertop surfaces, I installed two cherry step pads for the

upper steps. The pads are about 5" by 4", and feature a

grooved top surface for traction. These will prevent all the footfalls

from landing directly on our sandwiches or on the steps, which are going to end up being a useful

part of the galley countertop. I installed the pads with screws from

beneath.

I've found that it often works best to come

down the first two steps and then turn around and back down the last three

steps. This is because the steps are so narrow and shallow, and therefore

work best when the front part of your foot extends into the opening. With

the heel, there's only a few inches of bearing surface, and it's a little more

awkward.

To complete the engine box portion of the

galley, I installed a number of various trim

pieces on the steps, engine box and around the galley. Details on the

trim can be found here.

|

|

Galley

Countertop and Stove

The

Triton was lacking a well-found galley in the original design, and one of the

first things I did was rip the old junk out.

Now, almost a year later, the time came to begin rebuilding. We

purchased a 2 burner stove with oven, and to accommodate it's size, come changes

needed to be made to the general cabin layout. The

Triton was lacking a well-found galley in the original design, and one of the

first things I did was rip the old junk out.

Now, almost a year later, the time came to begin rebuilding. We

purchased a 2 burner stove with oven, and to accommodate it's size, come changes

needed to be made to the general cabin layout.

In order for our new stove to fit, it was

necessary to shorten the starboard berth somewhat, and also to cut out the

settee platform to allow the stove to sit at the proper height. Using

the dimensions provided with the unit, I marked the settee where cuts were

necessary, and cut it out with a jigsaw.

|

|

With

the cutout made, I used a tick strip to measure

and make patterns for the two bulkheads that will go on either side. The

forwardmost bulkhead will be seen and was cut from 1/2" cherry plywood;

the after bulkhead will not be seen in the final installation and was cut from

marine merranti plywood. With

the cutout made, I used a tick strip to measure

and make patterns for the two bulkheads that will go on either side. The

forwardmost bulkhead will be seen and was cut from 1/2" cherry plywood;

the after bulkhead will not be seen in the final installation and was cut from

marine merranti plywood.

To install the bulkheads, I added cleats

where necessary, and, when I was sure of their position, I glassed portions of

the bulkheads to the hull. Because I had previously painted nearly the entire

inside of the hull and lockers with Bilgekote, knowing that some areas would

become inaccessible as I constructed the interior, it was necessary to grind off

any paint that was located where I needed to install fiberglass tabbing.

|

|

To

help support the galley countertop, and also to subdivide the large space

beneath, I installed a small bulkhead/divider there. Because it is lower

than the one in the picture, you can't really see it in this view. It can

be seen in some of the other pictures in this section, though. To

help support the galley countertop, and also to subdivide the large space

beneath, I installed a small bulkhead/divider there. Because it is lower

than the one in the picture, you can't really see it in this view. It can

be seen in some of the other pictures in this section, though.

|

|

Next, I continued the stove enclosure by

adding a bottom and back to the opening. After consulting the owners

manual for the stove again, with its measured drawing, I screwed cleats to the

sides of the enclosure where necessary to support the new pieces. This

includes an angles section at the back of the bottom in order to conform to

the hull. Then, I cut plywood to fit the spaces; the plywood will later

be covered with Formica. This created a nice pan storage area

immediately behind the stove, beneath the partial countertop. Next, I continued the stove enclosure by

adding a bottom and back to the opening. After consulting the owners

manual for the stove again, with its measured drawing, I screwed cleats to the

sides of the enclosure where necessary to support the new pieces. This

includes an angles section at the back of the bottom in order to conform to

the hull. Then, I cut plywood to fit the spaces; the plywood will later

be covered with Formica. This created a nice pan storage area

immediately behind the stove, beneath the partial countertop.

|

|

This

shows the new stove enclosure after installing the various plywood pieces over

the cleats I installed. The two pieces on the eh bottom will remain

removable to provide access to the plumbing that will be installed underneath

a little later on. This

shows the new stove enclosure after installing the various plywood pieces over

the cleats I installed. The two pieces on the eh bottom will remain

removable to provide access to the plumbing that will be installed underneath

a little later on.

|

|

I

cut two pieces of plywood to fit over the galley area. Once I determine

the sink I am using, and cut a couple access hatches to the storage areas

beneath, the plywood can be permanently installed and covered with

Formica. I

cut two pieces of plywood to fit over the galley area. Once I determine

the sink I am using, and cut a couple access hatches to the storage areas

beneath, the plywood can be permanently installed and covered with

Formica.

First, though, I had to cut some access hatches

for the storage areas that were created beneath the new countertops. I

marked off the size of the openings I wanted and cut them with a jigsaw, and

screwed wooden cleats around each opening to support the flush hatches.

|

|

With

that out of the way, I went ahead and installed more satin white Formica over

the surfaces of the galley, including the inside of the stove enclosure.

Later, the exposed edges of plywood and other junctures will get covered

with pieces of solid cherry trim. Please visit the interior

trim page to see details on this trim work. With

that out of the way, I went ahead and installed more satin white Formica over

the surfaces of the galley, including the inside of the stove enclosure.

Later, the exposed edges of plywood and other junctures will get covered

with pieces of solid cherry trim. Please visit the interior

trim page to see details on this trim work.

|

|

I enclosed the final remaining areas behind

the stove and aft portion of the galley countertop with cherry plywood, cutting

it to fit as necessary. I cut openings in the face to allow access to the

compartments behind. The placement and general configuration of these was

determined arbitrarily by eye, and everything is installed with screws and

wooden cleats as needed. The cabinets outboard of the countertop,

especially the after two, are difficult to reach because of the cockpit molding;

I don't expect to use them for important items. I will still be able to

reach inside the upper cabinets in order to install the genoa track and any other

deck hardware in the area. I enclosed the final remaining areas behind

the stove and aft portion of the galley countertop with cherry plywood, cutting

it to fit as necessary. I cut openings in the face to allow access to the

compartments behind. The placement and general configuration of these was

determined arbitrarily by eye, and everything is installed with screws and

wooden cleats as needed. The cabinets outboard of the countertop,

especially the after two, are difficult to reach because of the cockpit molding;

I don't expect to use them for important items. I will still be able to

reach inside the upper cabinets in order to install the genoa track and any other

deck hardware in the area.

|

|

Please click

here to continue the galley construction project.

For more information on finish work in the

galley, please visit the following pages:

Trim details

Galley Sink and

Water Systems

Installing the

Stove and LPG Supply System

|

|